| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Linear Shaft Supports |

|---|---|

| Brand Name: | OEM |

| Model Number: | SHF50 |

| Certification: | DE1924083895474 |

| Place of Origin: | CHINA |

| MOQ: | 10 |

| Price: | 1-100 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,Western Union |

| Supply Ability: | 100000 pcs / per month |

| Delivery Time: | 1-7 work days |

| Packaging Details: | Small or with carton box, Bulk order with Wooden box |

| Shaft Diameter: | 50mm |

| Shape: | Flanged type |

| Material: | Aluminum Alloy |

| Shaft Securing Method: | Slit |

| Surface treatment: | Clear Anodize |

| Mounting Hole Type: | Through hole |

| Thickness: | Standard |

| Dowel hole: | Not provided |

| Clamp lever: | Not provided |

| Application: | Electronic & Electrical Appliances, Robotics, Automotive |

| Company Info. |

| NanJing TranzBrillix Linear Motion Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

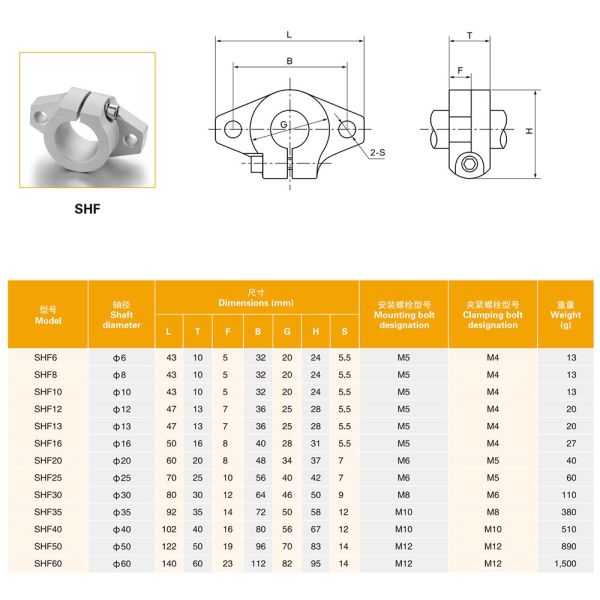

The SHF50 Flanged Linear Shaft Support Blocks offer a heavy-duty mounting solution for 50mm motion systems, featuring a robust flanged design that delivers unparalleled stability and load-bearing capacity. The oversized flange provides an expansive mounting surface that distributes forces evenly across the support structure, effectively counteracting the high moment loads encountered in large-diameter shaft applications. This flanged configuration enables secure mounting to equipment frames with multiple fastener points, creating a rigid foundation that maintains precise alignment even under substantial operational stresses. The flange's extended profile enhances vibration damping characteristics while providing improved resistance to torsional forces that could compromise system accuracy. Precision machining ensures perfect perpendicularity between the mounting face and bore axis, critical for maintaining smooth linear motion in high-capacity systems. The flanged design proves particularly valuable in industrial automation equipment and material handling systems where 50mm shafts require exceptional support against deflection. The generous flange dimensions allow for flexible mounting arrangements while providing ample surface area for secure attachment to structural components. This heavy-duty flanged solution combines the benefits of positive location with the strength required for demanding applications, offering engineers a reliable foundation for large-scale linear motion systems where both precision and durability are paramount. The thoughtful flange geometry ensures long-term performance in applications ranging from industrial machinery to automated production lines handling substantial loads.

② Features of linear shaft supports

Feature 1: Tool-Free Slit Design

The innovative slit design of the shaft supports enables quick,

tool-free installation and secure connection to shafts without

causing surface damage or compromising structural integrity,

ensuring hassle-free assembly and disassembly.

Feature 2: Cost-Efficient Aluminum Extrusion Manufacturing

The economy series shaft supports utilize advanced aluminum

extrusion technology, offering a lightweight yet durable solution

at a significantly reduced cost. While precision is marginally

lower compared to fully machined alternatives, this series

maintains sufficient accuracy to meet the functional requirements

of most applications, delivering exceptional value for

budget-conscious projects.

Feature 3: Fine-Adjustment Through-Hole Tolerance

The precision-engineered clearance in the installation through-hole

allows for on-site micro-adjustments, enabling users to achieve

optimal shaft alignment and positioning during final assembly. This

feature eliminates the need for additional components, streamlining

setup in dynamic operational environments.

Feature 4: Standardized Stock Availability

Available in inner diameters ranging from 6mm to 60mm (exact

specifications provided in the product catalog), the economy series

shaft supports are maintained as standardized stock items. This

ensures rapid order fulfillment with same-day shipping

capabilities, minimizing downtime and accelerating project

timelines for time-sensitive applications.This combination of

user-centric design, affordability, adaptability, and rapid

availability positions these shaft supports as a versatile solution

for both industrial and commercial linear motion systems.

⑤Actual product photo

|