| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Fiber Laser Metal Cutting Machine |

|---|---|

| Brand Name: | QIHAI |

| Model Number: | QH-GS |

| Certification: | CE, ISO |

| Place of Origin: | Foshan, Guangdong, China |

| MOQ: | 1 Set |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 100 Set/month |

| Delivery Time: | 50 days |

| Packaging Details: | wood |

| Control software: | Cypcut,Ruida,Perfect Laser Professional Laser Cutting Software,PhotoShop,TAJIMA |

| Cnc or not: | Yes |

| Graphic format supported: | PLT,DXF,AI,BMP,DST |

| Cutting thickness: | Depends,Materials,0-20mm,30mm acrylic,0-15mm |

| Cooling mode: | Water Cooling |

| Warranty: | 1 Year |

| Laser power: | 500W / 1000W / 2000W / 3000W,500-3000W,100W/130W/150W/280W,150W reci,80w/100w/130w/150w |

| After-sales service provided: | Engineers available to service machinery overseas |

| Laser source: | IPG/Raycus,1000W,Raycus IPG,World Famous Germany DLaser Fiber laser source |

| Color: | White,according to client,Required,Blue and white |

| Company Info. |

| Qihai Laser Tech. Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

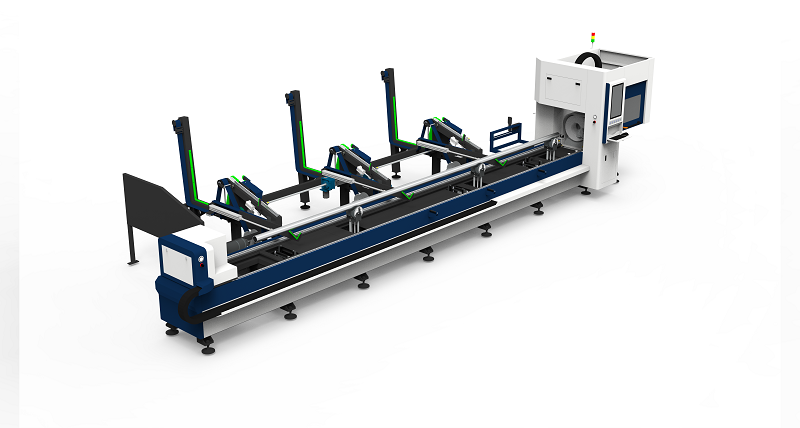

Fully-automatic Loading Core: End-to-end auto conveying/alignment/clamping/unloading (cuts total cycle time by 50% vs. semi-auto); QH-GZ for heavy thick tubes, QH-GS-6012 for compact-space multi-thickness use.

Shared & Variant Specs: Φ15-500mm round/15×15-500×500mm square tubes (5500-6500mm length, ±0.03mm accuracy); QH-GZ: 6000W-20KW/2T/9620×2950×2080mm; QH-GS-6012:1500W-20KW/1.7T/8500×1380×2050mm.

Fit: High-volume batch processing (pipelines/machinery); fully auto loading eliminates manual lifting/inconsistency.

| Model | QH-GS-6012 |

|---|---|

| Cutting Diameter | Round Tube: Φ15-500mm Square Tube: 15*15mm to 500*500mm |

| Tube Length Capacity | 5500-6500mm |

| Machine Weight | 1.7T |

| Dimensions (L*W*H) | 8500*1380*2050mm |

| Laser Power Range | 1500W-20KW |

| Positioning Accuracy | ±0.03mm (X/Y-axis) |

| Repositioning Accuracy | ±0.03mm (X/Y-axis) |

| Compatible Tube Types | Round Tube / Square Tube |

Fully-automated Workflows Slash Cycle Time: Unlike semi-auto loaders that require manual handoff for unloading, the system completes “feed-align-cut-unload” in one loop. For a batch of 100×6500mm Φ300mm round tubes, QH-GZ cuts total processing time from ~4 hours (semi-auto) to ~1.8 hours—critical for meeting high-volume orders. The auto-unloading also eliminates bottlenecks from manual material handling, boosting daily throughput by 60%-70%.

Heavy Tube Handling Reduces Labor Risks: QH-GZ’s Fully-automatic Loading system handles tubes up to 150kg/m (e.g., 25mm-thick carbon steel pipes) via motorized rails and hydraulic clamps, eliminating manual lifting (which reduces worker injury risk by 90%+). This contrasts with semi-auto setups where 2-3 workers are needed for heavy tube positioning—cutting labor costs by 50%-60% for 24/7 operations.

Consistent Alignment Boosts Precision & Yield: The fully automated alignment system uses laser positioning to calibrate tubes within ±0.02mm (matching the machine’s ±0.03mm accuracy), avoiding manual alignment errors (common in semi-auto setups) that cause 8%-12% scrap rates. For high-precision pipeline components, this ensures every cut tube meets weld-joint tolerances, reducing rework by 85% and scrap costs by 40%-50%.

Variant-specific Loading Adaptability Fits Diverse Needs: QH-GS-6012’s compact Fully-automatic Loading mechanism uses a foldable conveying arm, fitting workshops with 9m-length limits (vs. QH-GZ’s 9.6m footprint) while still handling full 6500mm tubes. QH-GZ’s reinforced loading system, meanwhile, pairs with its 6000W-20KW power to process thick-wall tubes in one pass—no need for secondary cutting, unlike machines with underpowered lasers or manual loading that require multiple setups.

|