| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | High Alumina Refractory Brick |

|---|---|

| Brand Name: | Jianxin |

| Place of Origin: | China |

| Certification: | CE |

| MOQ: | 1pcs |

| Price: | 1000usd |

| Material: | High Alumina |

| Condition: | Brand New |

| Keyword: | 55% Al2O3 High Alumina Brick |

| Chemical Resistance: | Good |

| Temperature: | 1700-1800℃ |

| Shape: | Rectangular |

| Package: | Wooden Pallet |

| Weight: | ≥ 3.2 Kg |

| Company Info. |

| Zhengzhou Jansincere Refractory Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

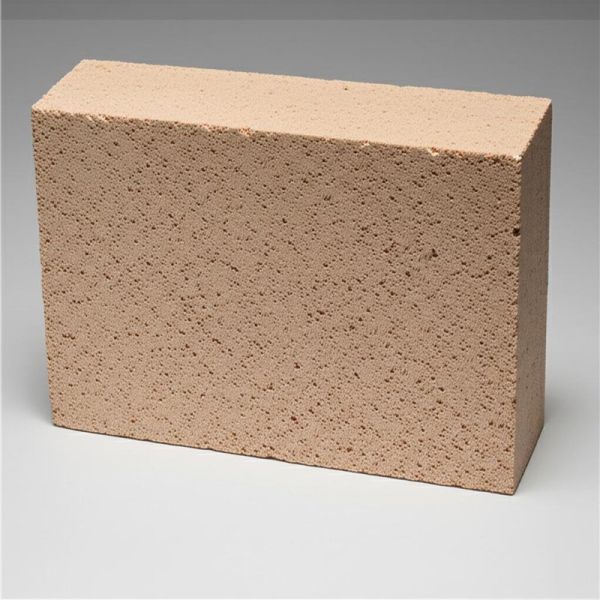

The High Alumina Refractory Brick is an advanced construction material designed to withstand extreme conditions, making it an essential component in high-temperature industrial applications. Known for its exceptional durability and thermal stability, this Alumina High-Temperature Brick is engineered to perform reliably in environments that demand superior heat resistance and structural integrity.

One of the key attributes of this Alumina High-Temperature Brick is its porosity, which is maintained below 22%. This low porosity level is critical as it significantly enhances the brick's resistance to thermal shock and chemical attack, ensuring a longer service life even under rigorous operating conditions. With a porosity of just 22%, the brick exhibits minimal permeability, thereby reducing the risk of damage caused by slag penetration and corrosion, which are common issues in high-temperature settings.

The surface of the High Alumina Refractory Brick is smooth, providing an excellent finish that facilitates easy installation and integration into various refractory linings. A smooth surface not only improves the brick's aesthetic appeal but also contributes to better bonding with refractory mortars and other materials, enhancing the overall structural stability of the installation. This smooth texture also aids in reducing the accumulation of dust and debris, which can otherwise impair performance over time.

Packaging is another important aspect of this Alumina High-Temperature Brick. The bricks are securely packed on wooden pallets, ensuring safe transportation and handling. This packaging method minimizes the risk of damage during transit and storage, preserving the quality and integrity of each brick until it reaches the point of use. Wooden pallets also facilitate easy loading and unloading, streamlining logistics and inventory management processes.

Designed for applications that require high-temperature resistance, this Alumina High-Temperature Brick performs exceptionally well in furnaces, kilns, incinerators, and other industrial equipment exposed to intense heat. Its ability to withstand high application temperatures without deformation or degradation makes it an ideal choice for industries such as metallurgy, cement production, glass manufacturing, and petrochemicals. The brick's thermal properties help maintain consistent internal temperatures, improving energy efficiency and operational reliability.

In summary, the High Alumina Refractory Brick combines low porosity, a smooth surface finish, and robust packaging to deliver a product that meets the demanding needs of high-temperature industrial environments. Its superior performance characteristics make it a trusted solution for engineers and technicians seeking durable and efficient refractory materials. Whether used in the construction of new facilities or the maintenance of existing equipment, this Alumina High-Temperature Brick ensures optimal performance and longevity, making it an invaluable asset in any high-heat application.

| Material | High Alumina |

| Alumina Content | 55% Al2O3 (Alumina High-Temperature Brick) |

| Porosity | Below 22% |

| Ash Content | 0.3% |

| Weight | ≥ 3.2 Kg |

| Surface | Smooth |

| Shape | Rectangular |

| Application Temperature | High (High Alumina Heat Resistant Brick) |

| Working Temperature | High (Alumina Fire Resistant Brick) |

The Jianxin 55% Al2O3 High Alumina Brick is a premium Alumina Refractory Fire Brick designed and manufactured in China, boasting CE certification to ensure top-quality standards. This brand new product is specially engineered for applications requiring exceptional resistance to high temperatures, withstanding operating temperatures ranging from 1700 to 1800℃. Its excellent chemical resistance makes it ideal for harsh industrial environments where durability and longevity are crucial.

This High Alumina Insulation Brick is widely used in various high-temperature industrial scenarios. It is perfect for lining furnaces, kilns, incinerators, and other heat-intensive equipment in sectors such as metallurgy, ceramics, glass production, and petrochemicals. The brick’s composition and structure allow it to maintain integrity and insulation performance even under prolonged exposure to extreme heat, making it a reliable choice for thermal insulation and fire protection.

In steel manufacturing plants, the Jianxin Alumina Refractory Fire Brick is commonly applied to lining the hearths, tuyere zones, and sidewalls of blast furnaces and electric arc furnaces, where temperatures often soar beyond 1700℃. Its high alumina content ensures resistance to slag corrosion and mechanical wear, significantly extending the service life of the furnace lining. Similarly, in cement rotary kilns, this High Alumina Insulation Brick helps maintain consistent high temperatures while reducing heat loss, enhancing overall energy efficiency.

Other notable application occasions include glass melting furnaces, where the brick's chemical resistance prevents degradation caused by molten glass and corrosive gases, and incinerators, where it helps contain and manage intense thermal cycles. The product’s robust nature also makes it suitable for use in boiler furnaces and power plants that require materials capable of withstanding both thermal shock and chemical attack.

With a minimum order quantity of just 1 piece and a competitive price of 1000 USD, the Jianxin 55% Al2O3 High Alumina Brick offers a cost-effective yet highly efficient solution for industries requiring advanced refractory materials. Its combination of high-temperature resistance, chemical stability, and insulation properties ensures optimal performance in demanding applications, making it a trusted choice for engineers and procurement specialists alike.

|