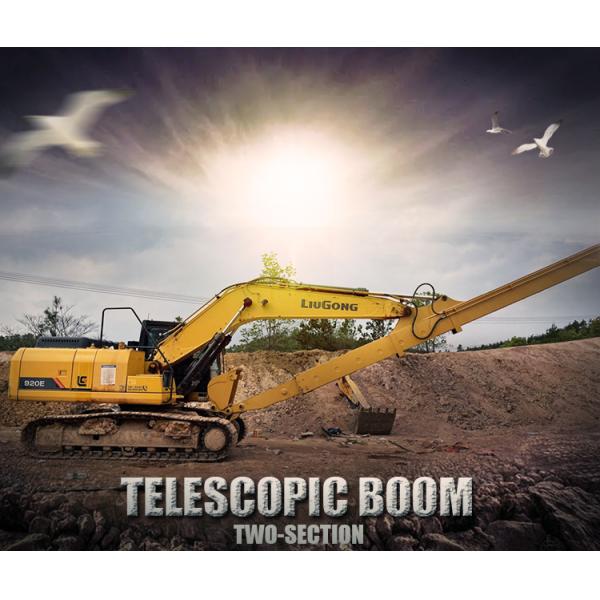

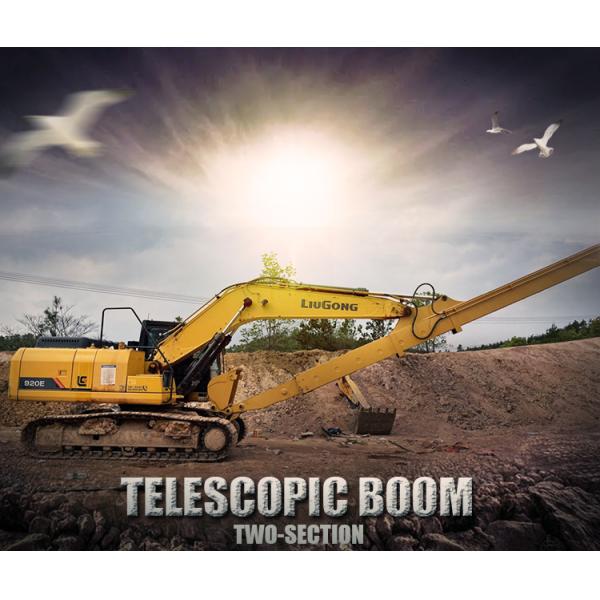

Introduction of Excavator Telescopic Boom with Bucket

Deeper digging depth:

The excavator telescopic arm two-section type is a remarkable engineering innovation that has revolutionized numerous industries. Its unique design allows for enhanced reach and versatility, making it an indispensable tool in construction, manufacturing, and various other sectors.

Our telescopic arm for excavator is hot-sale with excellent design and mature technology.

Features of Adjustable Excavator Telescopic Arm

(Robust structure)

1. Bearing part with multi-layer reinforced

(Long service life)

1. The reel adopts enlarged spring piece 2. Adopt 22-ton strong bucket cylinder

(Avoid oil leakage)

1. Hydraulic hoses are made of four-layer steel wire ring. 2. The telescopic cylinder adopts double oil seals 3. Bucket cylinder hose was built-in to avoids oil leakage caused by hose vibration

(Easy to maintain)

1. Lubrication system for sliders help support butter easily. 2. Bucket cylinder hoses can be replaced easily, without dismantling the arm.

Advanatges of two-section arm

1.Suitable Working Conditions

Digging downwards, suitable for various narrow working conditions: Dig caissons, deep pits, house foundation pits, etc.

Digging depth is very deep, suitable for digging soft soil silt.

2.Main Material we choose is Q690/ HG785/LG700

Lighter and stronger

The main material of arm tube we use is Q690D/HG785/LG700

Enhance longer life-span, lighter and stronger

The other place we use Q355B.

3.Two Section Telescopic Arm Excavator

Enlarge Spring Leaf. Most of the telescopic arm for excavator are dug downwards, and the exposed hoses can easily scratch obstacles, which may cause pipe bursts and oil leakage problems. The design of the hose reel and the built-in hose can avoid such problems.

Enlarge spring leaf also enhance the working efficiency.

The telescopic arm of excavator can be placed flat on the ground when it is lowered, and will not exceed cab or be super high.

Specification

Two Section Telescopic Arm Configuration

1. A set of telescopic arm

2. Eight high-pressure hoses

3. Nine pins

4. A standard bucket

5. A two-way foot switch

6. A bucket cylinder

7. A set Linkage

ZHONGHE triple quality control system

The first system is the technical design drawing review mechanism,

The second system is the semi-finished product review mechanism,

(each process has a detection testing for the previous process)

The third system is the finished product testing.

(Before painting, the overall inspection is carried out to check whether the design size matches the welding size, and whether the installation size meets the design requirement.)

To sum up, every single ZHONGHE product has been passed the above three-stage inspection system to ensure that is qualified before shipping.

The equipments we have:

Production Process

Quality Control--Ensure High Quality Telescopic Arm for Excavator

Quality Control--Ensure High Quality Telescopic Arm for Excavator

Shipping And Packaging

Our products have been sold to more than 60 countries, and our transportation methods include sea transportation, land transportation, and air transportation. Our packaging is wooden box packaging or stretch film packaging. The goods will be packed before shipment and then loaded into the container to ensure the safety of the goods.

Q: Are you a manufacturer?

A: Zhonghe machinery offered a wide range of attachment parts for excavators and dozers. Such as long reach arm, demolition arm, telescopic arm, standard bucket, rock bucket, cleaning bucket, tilting bucket, etc. We know that the perfect combination of high-quality cast steel products and a moderate price is the key to the success.

Q: Why choose Zhonghe over any other companies?

A: We have a professional production team and design team to provide each customer with high-quality and personalized customer service to ensure correctness, so we have good reputation in China, and our annual sales are among the best in our country.

Q: What can I get from you?

A: 1. The product is made of Q355B steel, a superior and sturdy material on the market, and the steel is cut with a 45-degree slope and then gas welded, making it more sturdy and 30% longer lifetime than normal materials. 2. All accessories are included, no additional purchases are required. Professional online video guides installation to make installation worry-free. 3. Lifetime free online customer service consultation if you have any questions.

Q: How do I start to order?

A: Firstly, talk to our sales about your machine model, working conditions, special needs and deadline. Then our sales will give you proposals FYR. You will receive a quotation ASAP after confirming the proposal.

Q: What are your terms of payment?

A: We prefer T/T (50/50) through Ali Credit Insurance as a trial order.

Q: Are you always delivered on time?

A: We can't promise about the sea freight but what we can do is shorten our lead time while keeping the same quality level. So there will not be any problem even if the sea freight is delayed for a couple of days.

| Contact Information | |

| Name: | Iris |

| Tel: | +8615362217237 |

| WhatsApp: | +8615362217237 |

| Mail: | whq@excavatorboomarm.com |

|

|

|

Jiangmen Kaiping Zhonghe Machinery Manufacturing Co., Ltd

Introduction

Kaiping Zhonghe Machinery is a leading manufacturer specializing in

high-quality excavator arms, booms, and attachments. With years of

expertise in engineering and production, we provide durable,

high-performance solutions for construction, demolition, mining,

and material handling industries. Our commitment to precision,

innovation, and reliability has made us a trusted partner for

businesses worldwide.

Core Products

Kaiping Zhonghe Machinery offers a comprehensive range of excavator

attachments designed to enhance efficiency and versatility in

various applications. Our key products include:

- Long Reach Arms – Ideal for deep excavation, dredging, and extended

reach applications.

- Telescopic Arms – Including two-section and three-section

telescopic arms for flexible operation in confined spaces.

- Sliding Arms – Work high efficiency in digging caissons, house

foundation, deep pits etc.

- Pile Arms Pile Booms – Engineered for piling, foundation work, and

heavy-duty lifting.

- Demolition Arms – Two-section and three-section demolition arms

built for high-impact demolition tasks.

- Tunnel Arms – Designed for underground construction and tunneling

projects.

- Heavy-Duty Rock Booms – Reinforced for extreme rock excavation and

quarrying.

- Grabbing Arms & Attachments – Including steel grabs, stone grabs,

and specialized buckets such as rock buckets, standard buckets,

grid buckets, and shell buckets for efficient material handling.

Why Choose Zhonghe Machinery?

Superior Quality & Durability

- Our products are manufactured using high-grade steel and undergo

rigorous quality control to ensure longevity and performance under

demanding conditions.

- Advanced welding techniques and stress-relief treatments enhance

structural integrity.

Customization & Engineering Expertise

- We offer tailored solutions to meet specific project requirements,

ensuring compatibility with various excavator models.

- Our R&D team continuously innovates to improve efficiency and

safety.

Global Standards & Certifications

- Compliant with international quality and safety standards, ensuring

reliability in diverse environments.

Competitive Pricing & Timely Delivery

- Cost-effective manufacturing processes allow us to provide premium

products at competitive rates.

- Efficient logistics ensure on-time delivery to clients worldwide.

Our Commitment

At Kaiping Zhonghe Machinery, we prioritize customer satisfaction

by delivering robust, high-performance attachments that maximize

productivity. Whether for construction, mining, or demolition, our

products are built to withstand the toughest challenges while

enhancing operational efficiency.

Partner with us for durable, precision-engineered excavator arms

and attachments—where quality meets innovation.

Contact Us Today!