| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Industrial Ultrasonic Cleaner |

|---|---|

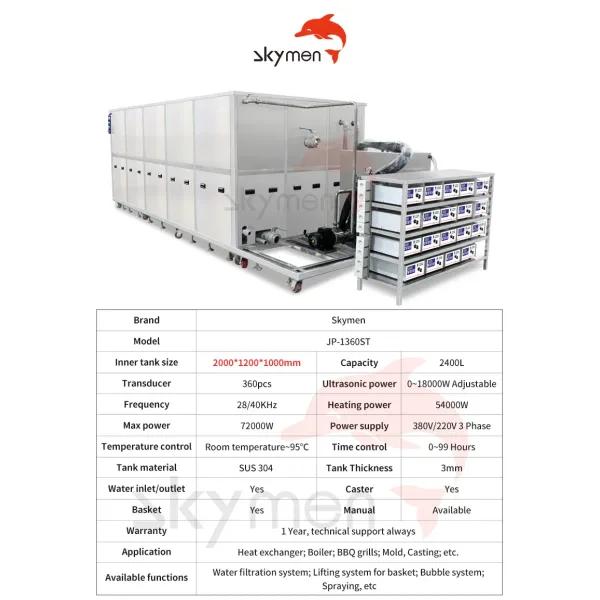

| Certification: | CE, RoHS |

| MOQ: | 1 |

| Price: | 3000 |

| Model NO.: | JP-1360ST |

| Cleaning Media: | Wet Cleaning |

| Cleaning Precision: | Ultra-Precision Industrial Cleaning |

| Material: | Stainless Steel SUS304 |

| Frequency: | 28kHz or 40kHz |

| Capacity: | 2400 Liters |

| Transducer Count: | 360 Pieces |

| Ultrasonic Power: | 18000W |

| Heat Power: | 54000W |

| Dimensions: | 2000*1200*1000mm |

| Tank Thickness: | 3 mm |

| Timer Range: | 1s-99 hours |

| Heater Range: | 20-95°C |

| Drain Valve: | 1 inch |

| Machine Voltage: | 380V/3 phase |

| Company Info. |

| Skymen Technology Corporation Limited |

| Verified Supplier |

| View Contact Details |

| Product List |

| Model | JP-1360ST | JP-1432ST | JP-1576ST | JP-1648ST |

| Tank size(MM) | 2000*1200*1000 | 2000*1500*1200 | 2500*1500*1200 | 3000*1500*1200 |

| Tank capacity(L) | 2400 | 3000 | 4500 | 5400 |

| Transducers | 360pcs | 432pcs | 576pcs | 648pcs |

| Ultrasonic power (W) | 18000 | 21600 | 28800 | 32400 |

| Heating power(W) | 54000 | 63000 | 63000 | 63000 |

| Frequency | 28K OR 40Khz | |||

| Tank material | 304 stainless steel | |||

| Tank thickness | 3 mm | |||

| Timer | 1s-99 hours | |||

| Heater | 20-95°C | |||

| Drain valve | 1 inch | |||

| Basket & Lid | Yes | |||

| Machine Voltage | 380V/3 phase | |||

| Features | With castor | |||

| Packing | Carton | |||

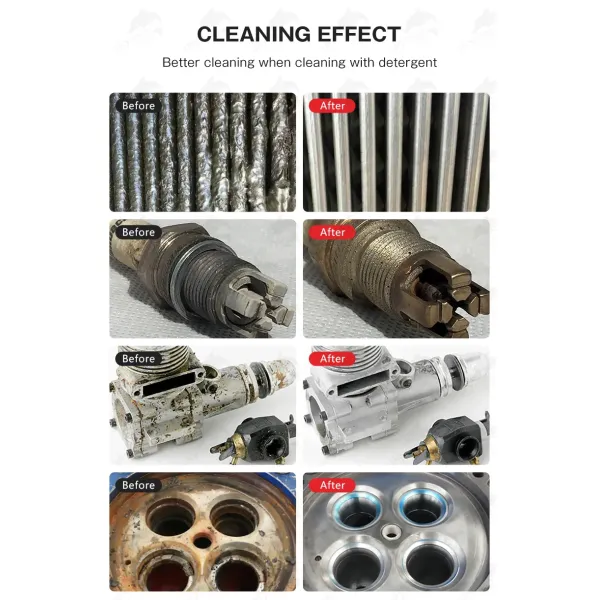

Electrical energy is converted into mechanical vibrations thanks to

special elaborated transducers.These vibrations are transferred

into the fluid through the walls of stainless steel.This creates

tiny microscopic vacuum bubbles, which cause consecutive implosions

(cavitation).The high-energy jets that are thus created can

efficiently remove dirt from surfaces an materials placed in the

cleaning bath.

An industrial ultrasonic cleaner can have an important role in

refurbishing equipment as well.

The refurbishing process includes taking the equipment apart;

cleaning the unit as well as any parts that can be salvaged;

replacing, repairing or upgrading damaged components; reassembling

the equipment; and then doing touch ups or cosmetic enhancements.

An ultrasonic cleaner is ideal for cleaning these parts prior to

reassembly, thoroughly removing any oils, coolants, or sludge build

up.

ultrasonic cleaning is faster than conventional aqueous cleaning

without damaging the parts.

Specifically, ultrasonic pre-treatment of parts allows for batch

processing and removes polishing compounds, etc. without staining

or reducing the adhesion in parts to be electro-plated. Ultrasonic

cleaning is perfect for degreasing tools and parts without manual

scrubbing,

capable of handling jobs that require both firm and gentle

cleaning. And in the process of refurbishing equipment, an

ultrasonic cleaner is perfect for cleaning parts before the

unit is reassembled.

FAQ:

How long do I need to clean my components for?

Cleaning time varies depending on the performance of your

ultrasonic bath and the level of contamination present.Different

conditions (temperature, ultrasonic power, detergent and detergent

dose) will all have an effect on the length of time required to

clean a component.

How do you clean an oil extractor pump?

"how to clean petroleum extraction machine

You need to clean the outer part of the oil extractor rubbing

thoroughly with it. After that flow alcohol deeply through the

internal systems of the oil extractor and the hoses. Alcohol would

dissolve those substances that water, even hot water cannot remove.

Then, apply hot water.

How much can I load into my ultrasonic cleaner?

The more instruments placed into an ultrasonic bath, the less

effective the cleaning cycle is going to be.It is not advisable to

place instruments in the basket so that they overlap as a more

effective clean will be generated if all surface areas are openly

exposed to the cleaning solution.However, filling a basket so

that there is clear space between instruments should lead to an

effective cleaning cycle.

Should the lid be on my ultrasonic cleaner when in operation?

The lid should be kept on the ultrasonic cleaner while in

operation.

The lid is for the protection of the operator and in medical

applications the patients also.It prevents aerosols generated

during the cavitation process from dispersing and contaminating the

reprocessing environment.In addition, the lid reduces the noise

levels created during the ultrasonic cycle and helps to maintain

the heat of the cleaning fluid in the tank.

|