| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

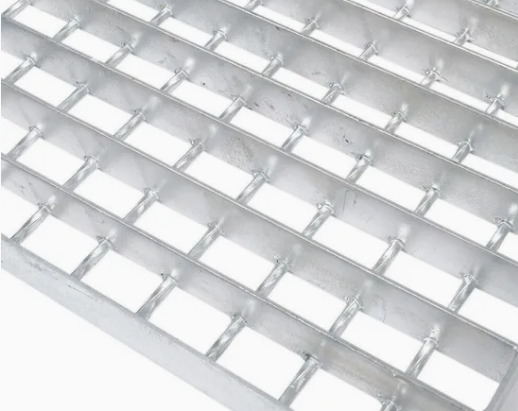

| Categories | Serrated Steel Grating |

|---|---|

| Brand Name: | GNEE |

| Certification: | SGS |

| Place of Origin: | China |

| Price: | Negotiable |

| Payment Terms: | Negotiable |

| Supply Ability: | 100 ton/week |

| Packaging Details: | Sea-worthy packing, ie wooden or steel tray with steel strip,etc |

| Company Info. |

| Gnee Steel (tianjin) Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Customizations

For customized steel grating solutions, we offer a wide range of

options tailored to your requirements, such as round holes or other

design modifications. Contact our customer service team for

inquiries and design needs.

To ensure optimal service, please provide us with your structure

drawings and detailed parameters. With this information, our

experienced team can recommend the ideal steel grating for your

application, saving you time and resources. We are committed to

delivering exceptional solutions that meet your precise needs and

offer significant cost and time savings. Don't hesitate to reach

out to us with your specifications.

Customer satisfaction is our priority. We take pride in delivering

high-quality steel grating products with punctual delivery and

competitive pricing. Contact us for detailed consultations,

inquiries, product specifications, or quotations. We eagerly await

the opportunity to serve you and fulfill all your steel grating

needs.

Steel Grating Maintenance

Steel grating maintenance is crucial to ensure its longevity and

functionality. Here are some key tips:

1,Check and tighten fasteners regularly.

2,Apply anti-rust paint to welded joints and repaint as needed.

3,Keep the grating surface clean and free from debris.

4,Maintain high-friction areas by inspecting and repainting them.

5,Periodically check and secure bolted connections.

6,Address any repair needs promptly with welding and anti-rust

paint.

7,Replace damaged gratings to prevent hazards.

These maintenance practices enhance corrosion resistance and

durability, improving production efficiency and preserving

environmental resources.

Item | Description |

Bearing Bar | 25x3, 25x4, 25x4.5, 25x5, 30x3, 30x4, 30x4.5, 30x5, 32x5, 40x5,

50x5, 65x5, 75x6, 75x10---100x10mm etc I bar: 25x5x3, 30x5x3, 32x5x3, 40x5x3 etc US standard: 1''x3/16'', 1 1/4''x3/16'', 1 1/2''x3/16'', 1''x1/4'', 1 1/4''x1/4'', 1 1/2''x1/4'', 1''x1/8'', 1 1/4''x1/8'', 1 1/2''x1/8'' etc |

Bearing Bar Pitch | 12.5, 15, 20, 23.85, 25, 30, 30.16, 30.3, 32.5, 34.3, 35, 38.1, 40,

41.25, 60, 80mm etc US standard: 19-w-4, 15-w-4, 11-w-4, 19-w-2, 15-w-2 etc. |

Twisted Cross Bar Pitch | 38.1, 50, 60, 76, 80, 100, 101.6, 120mm, 2'' & 4'' etc |

Material Grade | ASTM A36, A1011, A569, Q235, S275JR, SS304, SS400, Mild steel & Low carbon steel, etc |

Surface Treatment | Black, self colour, hot dip galvanized, painted, spray coating |

Grating Style | Plain / Smooth, Serrated /teeth, I bar, serrated I bar |

|