VC Vanadium Carbide Powder For Wear-Resistant Coatings

|

Product Description: Vanadium Carbide (VC) is a hard, refractory compound composed of vanadium and carbon. It is known for its exceptional hardness, thermal stability, and wear resistance, making it an important material in various industrial applications......

Zhuzhou Jiangwu Boda Hard-Facing Materials Co., Ltd.

|

Wc-12co 1342VM Woka3102 Tungsten Carbide Powder For Thermal Spraying Carbide Metal Water Conservancy Carbide Metal

|

Wc-12co 1342VM Woka3102 Tungsten Carbide Powder For Thermal Spraying Carbide Metal Water Conservancy Carbide Metal Product Description 88WC-12Co is a tungsten carbide powder for HVOF thermal spray coatings. It has performance feature such as Low ......

Changzhou WL Allotech Material Co.,Ltd

|

65 Silicon Carbide Powder For Refractory Material In Metallurgical Industry

|

|

...Carbide Powder for Refractory Material Strict Control and Complete After-Sales Service for Guaranteed Satisfaction 65 Silicon carbide is used in steel rolling processes in the metallurgical industry 65 silicon carbide can also be used in the steel rolling process. Silicon carbide is used as a slide rail in the heating furnace. At the same time, 65 silicon carbide can also be used in non-metallic ceramic heat exchangers. Silicon carbide...

Zhenan Metallurgy Co., Ltd

|

Rare Metals WC Tungsten Carbide Powder Wear Resistant For Cutting Tools

|

...metals purity tungsten powder spot goods high quality outlet Brief introduction Tungsten carbide powder (WC) is the main raw material for the production of cemented carbide, metallic luster, hardness similar to diamond, as a good conductor of electricity and heat, tungsten carbide insoluble in water, hydrochloric acid and sulfuric acid, easily soluble in nitric acid - hydrofluoric acid mixture. Pure tungsten carbide......

Luoyang Forged Tungsten-Molybdenum Material Co., Ltd.

|

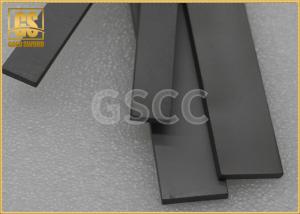

Wear Resistant Tungsten Carbide Strips With 100% Tungsten Carbide Powder Material

|

...Carbide Strips With 100% Tungsten Carbide Powder Material Tungsten Carbide Strips Description: Tungsten Carbide Strips shows all the superiorities of tungsten carbide, such as good wear and corrosion resistance, high toughness, etc. Precisely speaking, its chemical composition is mainly tungsten carbide powder, with Co or Ne as its binder. Tungsten Carbide Strips with several TC Grades used for various metals and non-metal...

Zhuzhou Gold Sword Cemented Carbide Co., Ltd.

|

Dark Gray Tungsten Carbide Metal Powder / Metal Spray Powder 5kg / Bottle Packaged

|

... Product Details Provides mono-crystalline WC-based, coarse-grain WC-based, casting WC-based and other kinds of PTA powder. With the high quality material, most...

Hunan TRX International Co., Ltd.

|

Hard And Brittle Refractory Raw Materials Green Silicon Carbide Powder F230-F400

|

|

... is suitable for grinding stems and brittle materials. Non-ferrous metals such as copper, bronze, aluminum, magnesium and non-metallic materials such as gems, optical glass, and rock , leather and rubber. It is also widely used as a refractory material and...

ZHENGZHOU CAIHUA KILN MASONRY INSTALLATION CO.,LTD

|

60-150 Welding Current Tungsten Wire for Cast Tungsten Carbide Powder 0.1mm Tolerance

|

...: Excellent Trial Order: Accepted Related Products: Cast Tungsten Carbide Powder Industrial Metal Powder Industrial Metal Powder Technical Parameters: Application Industrial, Lighting, Heating Processing Method Forging, Rolling, Drawing,Twisting Package...

Baoji City Changsheng Titanium Co.,Ltd

|

90% Purity 9.5 Mohs Black Silicon Carbide Powder For Metal And Wood Grinding

|

|

25.00cm * 25.00cm * 25.00cm Black Silicon Carbide for Metal and Wood Grinding Artificial Abrasive Type Silicon Carbide Abrasive Product Description Black silicon carbide is a high-quality abrasive material made from silicon carbide grains and petroleum ......

Luoyang Haocheng Abrasive Tools Co., Ltd

|

Metal/Carbide Injection Molding Dewaxing Vacuum Moulding Furnace

|

Metal/Carbide injection molding dewaxing vacuum moulding furnace Metal Injection Moulding (MIM) is a modern manufacturing technique that involves injecting a “feedstock” into moulds to create complex shaped metal components. Metal Injection Moulding (MIM) is a manufacturing technique that involves injecting a “feedstock” into moulds to create complex shaped components with a high rate of reproducibility. The feedstock is a mixture of powdered...

Zhuzhou Ruideer Metallurgy Equipment Manufacturing Co.,Ltd

|