Mirror Surface Laser Metal Sintering Injection Mold 500k

|

Laser Metal Sintering It is a process where metal powder particles are fused selectively by a high power scanning laser beam,and solidify in succesive layers, generating a tridimensional shape. Parameter Brand Name Gennki Group Description Plastic Injection Mould Material Metal Plastic Material Metal......

Gennki Group

|

Fishing Equipment Metal Injection Molding Parts Sintered Metal Components

|

...Metal Injection Molding Parts Sintered Metal Components Product Details:Metal Injection Molding parts molding sintering parts MIM PIM of Bicycle Parts Fishing Equipment Musical Instruments Material: SUS304 Surface:polishing Rugosity:Ra1.6 Tolerance:0.05-0.1mm L*W*H(mm)=50mm*50mm*12mm Main product display: Metal:SUS316,SUS630,SUS410,SUS304,SUS420,SUS440 Machine:Injection molding machine,Sintering......

Hongkong Winhoo Precision Co., Ltd

|

High Precision Custom MIM Steel Sintering Process Metal Injection Molding Parts

|

...Sintering Process Metal Injection Molding Parts Powder Metallurgy Metal Accessories Description: Introducing our High Precision Custom Mim Steel Sintering Process Metal Injection Molding Parts, the perfect solution for all your powder metallurgy metal accessory needs. Crafted with precision and attention to detail, these parts are made using the cutting-edge metal injection molding......

Beijing Oriens Technology Co., Ltd.

|

40HRC Metal Injection Molding Parts Metal Hook Parts With MIM Process

|

...Metal Injection Molding Parts Metal Hook Parts With MIM Process Brand name OEM & ODM Product type metal hook parts Product Model OEM Material Stainless steel 17-4PH Post-Sintering Polishing,Sandblasting,etc. Size Customized Tolerance ±0.1mm Weight 40-60g Forming Method Powder Injection Molding Sintering method vacuum sintering Sintering environment Vacuum Mold......

sints precision technology co.,ltd

|

440C Metal Sintered Spare Parts 316L Metal Injection Moulding Communication Accessories

|

... hydraulic press, automatic mechanical press, shaping machine, mesh belt furnace, vacuum furnace, high-precision EDM molding machine, CNC and other mold processing equipment, which can provide fast part molding services. At...

Guangzhou Herong Intelligent Device Technology Co., Limited

|

Easy Maintenance Metal Injection Molding Furnace Cooling Period ≤5h / ≤6h / ≤8h

|

...Metal Injection Molding Furnace Cooling Period ≤5h / ≤6h / ≤8h MIM Debinding Sintering Furnace Metal Injection Molding (MIM) Debinding Sintering Furnace MIM debinding sintering furnace is mainly used for debinding sintering process of stainless steel, ferrous, titanium, alloy steel and high speed steel metal injection molding parts. Products Characteristic 1. The MIM debinding & sintering......

Zhuzhou Ruideer Metallurgy Equipment Manufacturing Co.,Ltd

|

500kg Vacuum Dewaxing Furnace , Metal Sintering Machine For Metal Injection Molding

|

...Sintering Furnace For PM Industry 1. Main Description MIM vacuum de-waxing and sintering furnace is designed for metal injection molding (MIM). The following functions could be carried out in the furnace: negative pressure de-waxing, pressure de-waxing with H2, vacuum sintering, atmosphere sintering, partial pressure sintering......

Easy Fashion Metal Products Co., Ltd.

|

Consumer Electronics 200g SUS 304 MIM Metal Injection Molding

|

...Metal Injection Molding Consumer Electronics Brief Introduction The molding process allows dilated (oversized due to binder) complex parts to be shaped in a single step and in high volume. After molding, the powder-binder mixture is subjected to steps that remove the binder (debinding) and sintering to densify the powders. End products are small components used in various industries and applications. Metal......

Suzhou STR-Precision Powder Injection Molding co.,ltd.

|

ODM Polish MIM Titanium Metal Injection Molding For Lock Car Key

|

...Metal Housing Stainless Steel material powder metallurgy metal injection molding sintered parts MIM products. How to work with us: 1. Send us 3D drawing (STEP/IGS/SolidWorks format etc. ) 2. Specify the requirements (quantity, material, and surface finish requirements etc) to us via email. Manufacturing range MIM Metal Injection Molding......

Shenzhen Biest Precision Technology Co., Ltd.

|

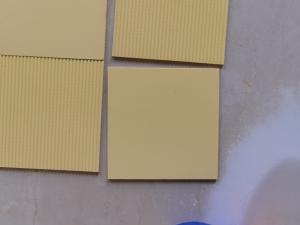

Setter Plates For Ceramic Injection Molding (CIM), Metal Injection Molding (MIM)

|

...molding (CIM), Metal Injection Molding (MIM) and Low Tempt Co-fired Ceramics (LTCC) A major advantage of ZG Solutions sintering trays is that they are composed of many refractory materials that are ideal for sintering applications. Our sintering trays are durable under a variety of furnace conditions and help maintain a high powder purity. High performance sintering......

HENAN ZG INDUSTRIAL PRODUCTS CO.,LTD

|