ABS PP Thermoplastic Foam Injection Molding ODM Multi Cavity Plastic Mold

|

...Injection Molding ODM Multi Cavity Plastic Mold ODM Design ABS PP Structural Foam Molding Black Multi Cavity Rapid Prototyping material ABS,PMMA,PC,PP,PEEK,PU,PA,PA+GF,POM,PE,UPE,PTFE,etc mould cavity single cavity & multi cavity runner system hot runner and cold runner equipment CNC, EDM, cutting off machine,plastic machinery etc mould material P20/ 718H/ S136H/ S136 hardened/ NAK80 injection......

Haoshun Mold Tech Co., Ltd.

|

Car Injection Molded Plastic Parts By Injection Multi Cavity Mould

|

...multi-cavity plastic injection molded parts for the plastic case Product Name Plastic injection mold Core &Cavity Steel P20,718H,2738H, H13, NAK80,2316 etc. Mould base & Standard Component DME,HASCO,Self-made etc. Steel hardness: HRC35-38 Plastic material PP,PC,PE,ABS,PVC etc. Cavity Number 1*1 Injection......

Dongguan Howe Precision Mold Co., Ltd.

|

Cold / Hot Runner Auto Injection Molding Machine Multi Cavities H45 - 52 Hardness

|

...Injection Molding Machine Multi cavities Mould Information: Mold information content Product Material ABS,PP,PC,PA,PMMA,PS,POM and etc. Moldbase FUTABA,LKM,HASCO,DME you can choose Cavity material 45#,50#,P20,H13, 718 2738, NAK80, S136, SKD61 etc Runner Cold/Hot runner Cavity Multi or single cavity......

Ningbo Haijiang Machinery Co.,Ltd.

|

ABS Plastic Injection Molds , HDPE Multi Cavity Injection Moulding For Soft Chair Arm

|

...Injection Mold , Multi Cavity Soft Chair Arm 1 . Soft Chair Arm 2 . Material:PP, PC, PS, PE, PU, PVC, ABS, PMMA ect 3 . Cavity:Multi 4 . Base:LKM, HASCO ect 5 . Runner :Hot 1.name Soft Chair Arm 2.plastic material TPU 70 degree 3.mould material P20 4.life 400,000shots 5. cavity multi 6. runner Cold 7.mould weight 430kg 8.mould size 500mm*450mm*400mm 9. mould base 45# 10. molding cycle 15 second 11.accessories of mold......

Weiyu Plastic Mould and Product Ltd.

|

100% Inspection Before Shipment OEM Injection Molding With Multi Cavity Design

|

...Injection Molding With Multi-Cavity Design Product Description: OEM Injection Molding is a one-stop solution for custom plastic parts manufacturing. We specialize in manufacturing high-precision injection molded plastic parts for OEM applications. Our injection molded......

Xiamen Creator Technology

|

High Standard Precision Injection Molding Tool , Multi Cavity Mold With Steel Material

|

...Mold Shaping Plastic mould ,plastic mold, plastic injection mold, plastic injection mould Colors You provide us PANTON# and we will match the colors Mold Base LKM & HASCO & DME Mold Material NAK80,S136,H13 ,718H,P20,and so on Mould Cavity Singe or multi as...

SHENZHEN JC RAPID MFG FACTORY

|

HASCO 2k Mold Multi Material Plastic Mold Parts / Multi Cavity Molds

|

...Mold Multi Material Injection Molding / Multi Cavity Molds Description 2K MOLD , Double Injection Mold , Multi Cavity Mold, Commodity Mould , HASCO MOLD Quick Detail: 1, export mould for automotive applications 2, material: PC/ABS +TPE , PC+TPU etc . 3, Cavity: 1+1 , 2+2 4, Base: LKM , HASCO etc . 5, Runner : Hot / cold Description: Material Type: S136 , SKD-61 , 1.2343 , 1.2311 ,738H Color: Natural Color Mould Cavity Steel: Multi......

FORWA PRECISE PLASTIC MOULD CO.,LTD.

|

Moldflow Injection Molding Tool Multi Cavity Mold Mold Bottle Top Tool Maker

|

Moldflow Injection Mold Tooling Multi Cavity Mold Bottle Top Tool Maker Please take following mold essential information for your reference: Part Material: Normal Plastic: PP,PE,EVA,PS; Engineering Plastic: PA,PA6,PA66,PC+ABS,PA46,PA+60%GF,PC,ABS,POM, PBT,......

NTT Mould Co., Ltd.

|

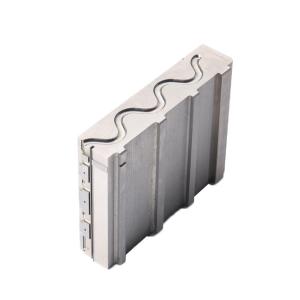

Injection Precision Mold Components Multi Cavity Inserts Simple Structure

|

Injection Moulding Core Cavity Inserts Mold Components Multi-Cavity Inserts Supplies We are sensitive enough in material handling, precision and craftmanship. All materials used in the production do the best of change and treatment. The process of mould......

TOXMANN HIGH-TECH CO.,LIMITED

|

Beverage Plastic Cap Packaging Mold Factory Multi Cavity injection molding mold cost

|

... with precision to redefine industry standards. These advanced molds are specifically engineered to cater to high-volume production demands without compromising on quality, embodying the perfect synergy between speed and accuracy. With their ability to...

Shenzhen Starlink Mold Co.,Ltd.

|