High Hardness CNC Tool Inserts Non Standard Grooving Inserts HYMG1809 HYMG1206 HYMG1608

|

... industries: Aerospace: Aerospace components usually have strict precision requirements and complex shapes. Non - standard grooving inserts can be customized according to specific design requirements to meet the high - precision processing needs of...

Sichuan Hanyu Haoyang Tools Co., Ltd.

|

FDAC Custom Plastic Injection Molding Non Standard Casting Insert Ejector Pin

|

...non standard Mold insert pin core insert pin casting insert ejector pin Standard: HASCO, DIN, DME , Rabourdin customized, non standard Material: H13, SKD61 or SKH51 Surface treatment:Nitriding, temper, PVD, TiCN etc Core pin is made by finest material H13, SKD61 or SKH51 etc. . The head is hot forged and stress relieved for uniform grain flow and high tensile strength . For some non standard......

Dongguan Datong Mold Fittings Co.

|

Non Standard Mold Inserts For Pharmaceutical And Personal Care Packaging

|

Non-Standard Mold Inserts for Pharmaceutical and Personal Care Packaging ABOUT US Dongguan SENLAN Mold Parts Co., Ltd. was established in 2006 and specializes in precision machining of mold components, particularly for non-standard customization in precision packaging molds. With years of industry experience and technical expertise, we provide efficient and professional mold parts processing services to global clients. Non-Standard Mold Inserts...

Senlan Precision Parts Co.,Ltd.

|

Non Standard Casting Insert Mold Core Pins

|

Customized Non Standard Mold Insert Pin Core Insert Pin Casting Insert Ejector Pin Place of origin Guangdong,China Main Products Die casting mold,Tungsten carbide,Plastic mold,Stamping die Year Established 2008 Main Markets North America 50.00%,Western ......

Dongguan Qy Hardware Mould Part Factory

|

Direct manufacturer Custom All Sizes CNC Tools Non-Standard Milling Cutters

|

... CNC machining application. These end mills are typically made from high-quality materials such as carbide, cobalt, or high-speed steel, and are precision-ground to ensure optimal cutting performance and accuracy. Custom end mills can be designed to meet a...

Supal (Changzhou) Precision Tools Co.,Ltd

|

304 stainless steel step screw flat head thumb screw non-standard welding insert screw

|

... process. The screw is similar in design to a traditional threaded screw, but it has a threaded hole at the top of the head that allows it to be welded to a surface. To use a welding insert screw, the screw is first inserted into...

Jiaxing Dexun Co.,Ltd.

|

CNC Milling Inserts Tungsten Carbide for High Temperature Alloy DIN GB Standard Carbide Milling Inserts

|

CNC Milling Inserts BLMP0603R-M BLMP0904R-M Tungsten Carbide for Stainless Steel parts Brand: "DELONG" or OEM We aim to OEM and cutomized order, we have the capacity of new design mold manufacturing for non standard carbide insert, cutting tools ......

Zhuzhou Delong Metal Materials Processing Co., Ltd.

|

Heavy Duty Milling Carbide Milling Inserts Non Standard Trigon Carbide Inserts

|

...face milling for larger parts, profile milling, milling of larger pockets, etc. The round inserts are extremely versatile and are the first choice for profile milling. They can be used for most milling such as face milling, pocket milling, round bottom...

Zhuzhou MMM New Material Co., Ltd.

|

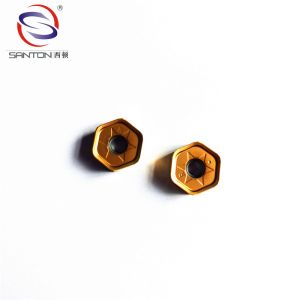

Roughing High Feed Milling Inserts indexable carbide inserts brazed tips

|

Non-Ferrous Metal Roughing Of Non-Metallic Materials High Feed Milling Inserts Grade Information: Santon Grade Density(g/cm³) TRS(n/mm²) HRA Performance & Applications ISO Code ST1050 14.5 3100 92 Extra fine substrate, higher strength, better impact and vibration resistance, good wear resistance, roughing and heavy milling of steel, stainless steel, gray cast iron, nodular cast iron, and non-ferrous metal, roughing of non......

Chengdu Santon Cemented Carbide Co., Ltd

|

High Feed Milling LNMU BLMP LOGU JDMT SDMT1205 09T308 SDMT Carbide Milling Insert

|

... to the processing of different metal (non-metal) materials, different materials of carbide milling inserts are selected. We usually recommend coatings according to the materials processed by customers to ensure the best cutting effect. 1.Low Moq 2. More...

Hunan Speed Carbide Tools Co.,Ltd

|