Custom Metalized Alumina Ceramics Parts for High Vacuum High Voltage and High Pressure Applications

|

... for power grid tubes, vacuum interrupters, RF windows, metallized rings, and various insulators and sensors. Material Properties Alumina is among the most widely used engineering ceramic materials, providing exceptional hardness, wear resistance,...

HENAN ZG INDUSTRIAL PRODUCTS CO.,LTD

|

Electrolytic Porous alumina Ceramic Membrane for Zinc Nickel Alloy Anode

|

... or steel, which can prevent chelating agents and other organic components from migrating from the electrolyte, to prevent the oxidation. The zinc nickel alloy anode electrolytic ceramic film produced by...

Yixing City Kam Tai Refractories Co.,ltd

|

Dense And Non-Porous Alumina Ceramic Ring Component For Electronics And Semiconductors

|

|

... structure consisting of an annular body + 6 sets of symmetrical notches + 6 positioning round holes. The product surface exhibits dense, non-porous characteristics after sintering at 1600°C, with...

Dayoo Advanced Ceramic Co.,Ltd

|

99% Porous Alumina Ceramic Plate Wear Resistant For Power Industry Ceramics

|

99% Wear-resistant Alumina Ceramic Plate Product Introduction The 99 Alumina Ceramic Plate is the most popular ceramic substrate, with excellent heat resistance,high mechnical strength , abrasion resistance and small dielectric loss. Made from superior ......

Zibo Huao New Materials Co., Ltd.

|

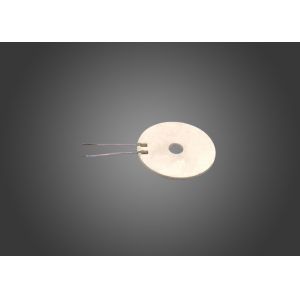

Piezoelectric porous alumina ceramic disc suspension ceramic insulator

|

... is made are readily available and reasonably priced, resulting in good value for the cost in fabricated alumina shapes. With an excellent combination of properties and an attractive price, it is no surprise that fine grain technical grade alumina has a...

Yixing Feifan Ceramics Co.,Ltd

|

Refractory Furnace Pipe 99% Alumina Ceramics With Excellent Properties Al2O3 Ceramic

|

Alumina ceramic is a precision ceramic material, which is currently a new ceramic material with a wide range of applications and high production and sales volume in oxide ceramics. Such as alumina ceramic chemical filler balls, inorganic microfiltration membranes, corrosion-resistant coatings, etc., among which the research and application of alumina ceramic membranes and coatings are more common. Naterial Unit A95% Alumina Ceramics A97% Alumina...

Yixing Hengyuan Ceramic Technology Co., Ltd.

|

Catalyst Porous Alumina Milling Media Beads Ceramic Grinding Balls

|

...Porous Alumina for Chemical Reactions Catalysts play a pivotal role in chemical reactions, enhancing rates and selectivity to produce desired products efficiently. Among the various catalyst support materials available, porous alumina beads are gaining popularity due to their exceptional properties and versatility. Understanding Porous Alumina Beads Porous alumina beads are spherical ceramic......

Guangzhou Zoli Technology Co.,Ltd.

|

Vacuum Tight Non Porous 99.5% Alumina Ceramic Components

|

...Alumina Ceramic Components Machining Parts 1. Description: AL-995 is a high purity 99.5% Alumina which due to its purity, chemical resistance and high temperature capabilities prove invaluable for semiconductor applications. This material benefits from the following features:1) Dense 2) Non-porous......

Loudi Antaeus Electronic Ceramic Co.,Ltd.

|

Personalized Non-Porous Alumina Nec Semiconductor Ceramic Heater Plate

|

|

Custom Alumina ceramic perforated suction plate non-porous sucking plates Semiconductor ceramics have semiconductor properties, electrical conductivity about 10-6 ~ 105S/m ceramics. Electrical conductivity of the semiconductor ceramics by external ......

Dongguan Ming Rui Ceramic Technology Co.,ltd

|

Tubular Membrane Filter Ceramic Membrane Ultra Filtration Plant For Micro Filtration

|

...Membrane Filter Ceramic Membrane For Micro Filtration Product Description Ceramic filtration membrane is an alternative core material for membrane separation technology. Ceramic filtration membranes are made of alumina, zirconia, titanium oxide, monox, kaolin and some other main raw materials to form support with porous structure, then functional membrane......

Chengdu Yuanjin Environmental Engineering Co., Ltd.

|