Magnetron Sputtering PVD Vacuum Coating Machine For Jewelry

|

...Warranty Full Auto PVD Coating Machine For Jewelry Other Configuration Working Theory Multi Arc + Magnetron Sputtering Operaiton Way Touch Screen Control System Full Automatic Heating System 1 Set Rotation Stand 1 Set PVD Coating Color Gold, Rose Gold, Silver, Blue, Gray, Black, Rainbow Jewelry PVD coating machine will choose multi arc for base coating and magnetron sputtering for surface coating. That will improve PVD coating......

Foshan Jinxinsheng Vacuum Equipment Co., Ltd.

|

Tantalum Sputtering Coating Machine

|

... in many industries because of its good resistance to erosion. Sputtered tantalum films are widely used in the 1. Microelectronics industry as the films can be reactively sputtered and thus resistivity and temperature coefficient of resistance can be...

SHANGHAI ROYAL TECHNOLOGY INC.

|

Full Auto AF Material Magnetic Sputtering film coating equipment Anti Fingerprint Sputter coating machine

|

...evaporation coating process, which significantly improves the quality of AF film layer. The products from the AF magnetic sputtering coate can meet the European CE standard. Detailed Introduction to AS AF Film PVD Magnetron Sputtering Coating Machine 1....

Hubei Lion King Vacuum Technology Co., Ltd.

|

Titanium Target Silicon Sputtering Target Gr5 Gr7 Pvd Coating Machine For PVD Vacuum Coating Machine

|

|

...our daily life. In the sputtering deposition process, the coating material is bombarded by the electron beam or ion beam, just like the target is hit, so the material used in the sputtering process is called the "sputtering target". From metal titanium to...

Baoji Lihua Nonferrous Metals Co., Ltd.

|

1600mm PVD Vacuum Coating Machine / Equipment Magnetron Sputtering Horizontal Continuous

|

PVD Magnetron Sputtering Machine Continuous Coating For Automotive Parts Chrome Plating Decoration Reflection Coating Goldstone is engaged to develop the professional vacuum sputter deposition system for customers’ flexible applications. The automobile mirror coating machine is designed for high quality front surface mirror and blue mirror. Goldstone is engaged to develop the professional vacuum sputter......

Sichuan Goldstone Orient New Material Technology Co.,Ltd

|

PVD Vacuum Coating Cylindrical Sputtering Targets

|

...Cylindrical Sputtering target for PVD Vacuum Coating Planar Sputtering target for PVD vacuum coating machine is widely used in Multi-arc ion or Magnetron Sputtering PVD vacuum coating industry for decorative PVD coating or functional coating, we can ......

JINXING MATECH CO LTD

|

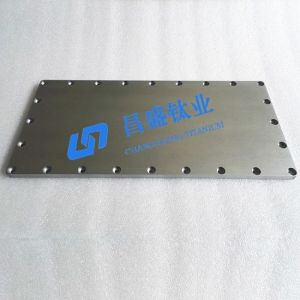

High Purity Cr Chromium Sputtering Target Plate Shape For PVD Coating Machine

|

Description Sputtering targets are materials used to grow thin films by the sputtering process. These targets are fabricated from high-purity metals or ceramics through advanced melting, sintering, synthesis, and precision machining techniques. We provide ......

Baoji City Changsheng Titanium Co.,Ltd

|

PVD Coating Tantalum Sputtering Target For Semiconductor Coating And Optical Coating

|

|

Product Information: Name PVD coating tantalum target Grade Ta1 Ta2 RO5200 RO5400 RO5252 RO5255 Purity ≥99.95% Density 16.68g/cm3 Surface Machined surface, no pits, scratches, stains, burrs and other defects Standard ASTM B708 Shape Flat target, Rotating ......

Shaanxi Peakrise Metal Co.,Ltd

|

12 Micron Vacuum Metallizing Machine Magnetron Sputtering Machine

|

...machine vacuum metallizing machine magnetron sputtering machine Product Description The machine use Vacuum metallizing technology match with Painting line to get all kinds of color metallic finishing on Products.We can do Turnkey Project for customers including Vacuum PVD coating......

Hefei Dongsheng Machinery Technology Co., Ltd

|

PVD and CVD Coated Spiral Inserts with ISO965-1980 DIN13 Standards and 3 Years Warranty for CNC Machining

|

Automated processing CNC tool inserts possess automation capabilities, facilitating automated machining operations through programming. High stability This stability can mitigate issues such as cutting vibrations and uneven surface quality, thereby further......

Chengdu Kedel Technology Co.,Ltd

|