CNC Stainless Steel Parts, Heat Treatment Of Nib Head, Vacuum Electroplating Black

|

...Stainless Steel Parts, Heat Treatment Of Nib Head, Vacuum Electroplating Black Quick Details: 1. CNC Machining or Not: CNC Machining 2. Color: As your requirement 3. Material: 303/ 304/ 316/ 304L/ 316L/ 17-4PH/ 1214L/ 1215/ 1045, etc. 4. Micro-processing or not: micro-processing 5 Tolerance: + / -- 0.002mm ~ + / -- 0.005 mm 6. Surface treatment......

Shenzhen Perfect Precision Product Co., Ltd.

|

PLC IGBT Induction Heating Machine For Stainless Steel Pipe Heat Treatment

|

...heating machine for stainless steel pipe heat treatment Induction heating is used for welding preheating and post-heating.It has the characteristics of good controllability:Can realize complex process program,Non-contact heating,Wide adaptability,High efficiency, Energy density,and ,Can realize on-line heating. Specifications New advanced tech induction heating machine for stainless steel pipe heat treatment......

Shenzhen Canroon Electrical Appliances Co., Ltd.

|

CNC Stainless Steel Parts, Heat Treatment Of Nib Head, Vacuum Electroplating Black

|

...Stainless Steel Parts, Heat Treatment Of Nib Head, Vacuum Electroplating Black Quick Details: 1. CNC Machining or Not: CNC Machining 2. Color: As your requirement 3. Material: 303/ 304/ 316/ 304L/ 316L/ 17-4PH/ 1214L/ 1215/ 1045, etc. 4. Micro-processing or not: micro-processing 5 Tolerance: + / -- 0.002mm ~ + / -- 0.005 mm 6. Surface treatment......

Shenzhen Perfect Precision Product Co., Ltd.

|

1.4545 Special Alloy Steel 15-5PH Stainless Steel Annealing Heat Treatment

|

15-5PH 1.4545 Stainless Steel Manufacturer 15-5PH Stainless Steel Factory 15-5PH grade is a martensitic precipitation and age hardening stainless steel with high strength and hardness together with excellent corrosion resistance. The chemical analysis is ......

Zhangjiagang Guangda Special Material Co., Ltd.

|

Stainless Steel Vacuum Heat Treatment Furnace For Vehicle Components

|

...furnace is principally adopted in Al brazing, Cu brazing and stainless-steel brazing of aerospace devices, vehicle components, electronic communicating devices, home appliances and various heat radiators. II. Technical specifications Specification/ Model ......

Easy Fashion Metal Products Co., Ltd.

|

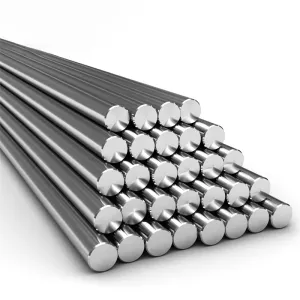

1 2 Stainless Steel Rod Heat Treatment Annealed / Quenched

|

Product Description: Stainless Steel Rod Bar The Stainless Steel Rod Bar is a type of metal product made of high-quality stainless steel material. It is widely used in various industries such as construction, manufacturing, and automotive due to its ......

Jiangsu Taigang Puxin Stainless Steel Co., Ltd.

|

Auto Wire Clips Stamp Sheet Metal Progressive Die Stainless Steel Vacuum Heat Treatment

|

Stainless steel auto wire clips stamp progressive dies by vacuum heat treatment processing Progressive stamping is a metalworking method that can encompass punching, coining, bending and several other ways of modifying metal raw material, combined with an ......

Xiamen METS Industry & Trade Co., Ltd

|

40Cr , 42CrMo4 Precision Ground Chrome Plated Steel Rod Heat Treatment

|

... Stainless Steel Rod Heat Treatment Detailed Product Description 1. Material: CK45, ST52, 20MnV6, 42CrMo4, 40Cr 2. Ground and chrome plated 3. ISO9001:2008 4. Condition: Chrome plated, Quenched / Tempered, Induction hardened, Q / T Induction hardened 5. ......

Jiangsu New Heyi Machinery Co., Ltd

|

Corrosion Resistance Sheets Stainless Steel For Heat Exchanger 904l Stainless Steel Plate

|

..., low temperature strength and mechanical properties; it has good thermal workability such as stamping and bending, and has no heat treatment hardening phenomenon. Widely used in household goods (category 1 and 2 tableware), cabinets, indoor pipelines,...

Jiangsu Hongtu Metal Technology Co.,Limited

|

Processing Steel Stainless Steel Carbon Steel Induction Heat Treatment Furnace For Hot Forging

|

...Steel, Stainless Steel, Carbon Steel by Induction Heat Treatment Furnace for Hot Forging About Induction Heat treatment Furnace Machine Induction heating is a growth sector, and for good reasons. The technique is energy efficient, reliable, reproducible, very fast and its range of possible applications is almost unlimited. For example, induction can be used: Annealing and normalising ,Bolt heating,,Bonding,Brazing,Forging,Hardening...

OURUIDA CO.,LTD

|