| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Sandwich Panel Production Line |

|---|---|

| Model Number: | Rolling Machine |

| Certification: | CE |

| MOQ: | 1 set |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 20 sets per month |

| Delivery Time: | 45 working days after receiving the 30% percent deposit |

| Packaging Details: | plastic film packaged to protect the machines , and the macines loaded into the container.The spare parts are packaged in the cantoon box, then loaded into the c |

| Forging Forming Method:: | Mold Forging |

| Use:: | roof |

| Production Capacity:: | 8-12m/min |

| Power(W):: | 5.5KW |

| Roll material:: | Forging Steel 45# Adjustable Treatment |

| Shaft material:: | 45# Steel Outer Diameter: 40mm |

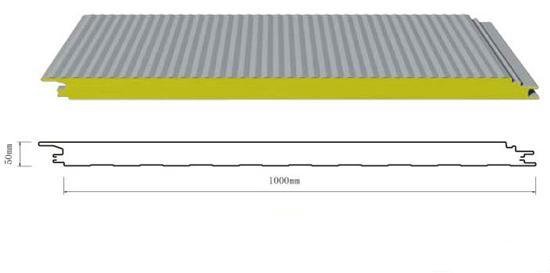

| Thickness:: | 0.3-1mm |

| Warranty:: | 12 months |

| Company Info. |

| RFM Cold Rolling Forming Machinery |

| Verified Supplier |

| View Contact Details |

| Product List |

Automatic PU Foam Sandwich Panel Production Line Roll Forming Machine For Building

Product description

Our company offers professional PU sandwich panel production line. Our PU foam machine is characterized by uninflammability, moistureproof capacity, insect-resistance, sound insulation, and light weight. Besides, it is never out of shape whether in dry or wet conditions. It has good heat preservation capacity.

PU Foam Line

Main technical parameters of the production line

1. Production type: totally continuous production with PLC controlling

2. PU foam thickness: 30-200mm

3. Standard Sandwich Panel Size:1000mm in Width

4. Sandwich panel length: as per the customer need

5. Linear speed of production: 2-6m/min

6. Reciprocating times of injection head per minute: <60

7. Composite structure: position fixed by double rubber belt conveyer

8. Foaming system: totally automatically continuous foaming, quantity of foaming could be stepless adjustable

9. Main Power of production: ≥ 45KW

10. Length cutting: pneumatic piston driving, non-stop cutting via sliding table

11. Electronic controlling system: PLC controlling system

12. Machine dimension: about 58 meter x 4 meter

13. Total gross weight: about 46 tons

Main components

| Hydraulic Automatic Decoiler | 2 Sets |

| Panel Roll Forming Machine | 2 Sets |

| PU Foaming & Injecting Machine | 1 Set |

| Belt Conveyer 24 Meter | 1 Set |

| Automatic Tracking Cutter | 1 Set |

| Product Table | 1 Set |

| Control Cabinet | 1 Set |

PU Foam Line

Working flow

Upper decoiling – roll forming

Bottom decoiling – roll forming – PU foaming & injecting – PU solidifying – length cutting – run out

PU Foam Line

Our service

Strictly product manufacturing and quality controlling to ensure every machine we sold is satisfied with our customer

Engineers available to service machine overseas, for example installation, training, etc

Lifelong service for spares, ware parts, technical supporting, etc

|