| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Bead Mill Machine |

|---|---|

| Brand Name: | AllWin |

| Model Number: | SP20 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 Unit |

| Price: | USD20000---25000/unit |

| Payment Terms: | T/T, Western Union, MoneyGram, L/C |

| Supply Ability: | 30 units /month |

| Delivery Time: | 20-30 working days |

| Packaging Details: | Wooden boxes |

| Volume: | 20L |

| Power: | 15kW |

| Materials: | Silicon Carbide Ceramics inner chamber or 304stainless steel |

| Warranty: | 1year |

| Explosion: | EX-proof |

| Used field: | Paper making, pesticide SC, oil, Paint,Food process |

| Saving Engery: | 10-20% |

| Mechanical seal: | Indepent technology |

| Lifet time: | >12 years |

| Wearing parts: | dispersing diks, sieve circle |

| Operation control: | button type control (PLC for optional) |

| Temperature control: | lower at least 5 degrees than general mills(decreased temperature is different from materials) |

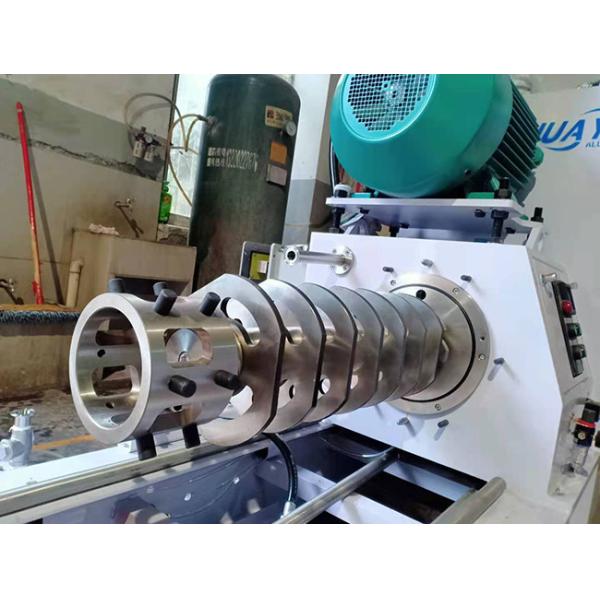

Energy Saving Durable Micron 20L Silicon Carbide Ceramics Wet Grinding Bead Mill Machine

The main characteristics:

1. Diversified material selection to meet different requirements;

2. Optimized cooling system design lower grinding temperature:

3. Controlling more factors strenghten the fineness:

4. Humanized overall design and experienced data enhance the

efficiency:

5. Sensitive alarm system reduce the workforce

The main parameter

1. Explosion proof motor: 15 kW 380V 50HZ

2. Effective volume of grinding chamber: 20L

3. Water pressure(Mpa): 0.3

4. Cooling water consumption: 2.5 -3m3/h

5. Dimension (L*W*H): 1500*900*1500mm

6. Weight: 1000Kg

| No | Main parts | SP5 Explosion-proof | Notes |

| 1 | External vessel | 304 stainless steel | |

| 2 | Inner grinding vessel | Silicon Carbide Ceramics | |

| 3 | Dispersing shaft | 40Cr with hard chromium plating | |

| 4 | Dispersing disk (agitator disk) | PU coated 304 stainless steel, | |

| 5 | Feeding and discharging end covers on the cylinder | 304 stainless steel | |

| 6 | Static discharge screen ring | Wire Wound screen ring with 304.Gaps: 0.5mm. | |

| 7 | Mechanical seal | Intelligent double mechanical seal with mandatory lubricating-cooling system | |

| 8 | Feeding pump | 1” ARO diaphragm pump; | |

9 | Appliance configuration | Explosion-proof machine, suitable for water base materials, motor 15kW. Explosion-proof parts: operation column,electrical appliance boxes;electric contact pressure gauge, temperature,solenoid valves with NO ex electrical contacts., Control system (button type) | |

| 10 | Fasteners and connecting parts | Stainless steel clamp-type connecting parts | Quick and convenient |

The Detailed parts

The button type control

Dispersing system

The Packing and Shipping

( The machine will be covered with anti-abrasion film and then packed in plywood cases. then sea shipping by FCL or LCL.)

After sales service:

1. Video instructions for installation and running test, if need, we will arrange engineer to your factory.

2. 60min feedback any customers questions, firstly offer the video help you solving, if need arrange maintenance engineer for you.

The Related production (Zirconia bead and dispersing machine)

Company Display

❸Service Aim: to creat values for user-centered customers.

❹Cooperation Principle: to solve the problem with mutual benefits.

FAQ:

Q1: Are you a trading company or manufacturer?

A1: We are the manufacturer.

Q2: Where is your company and factory located? How can I visit you?

A2: Our company is located in Tongxing industrial zone in Caijia Town, Beibei, Chognqing, China. Post code: 400709. It takes about 0.5 hours from Airport to our coampny by car. All our potential clients, from home or abroad, are warmly welcomed!

Q3: Do you have own R&D team?

A3: Yes, we have 12 engineers, and our products could be customized for your requirements.

Q4: How about the quality?

A4: We have professional engineers and a strict QA& QC system, Our factory comply with the IS09001 standard strictly.

Q5: What is your after-sale service?

A5: we offer 100% guarantee on our product and agree 1:1 replace defective products. Firstly we offer the video instruction for maintenance for you ,if need ,we will arrange engineer for you.

Q6: How is the payment?

A6: Firstly paid the deposit, then paid the balanced before shipping.

Q7: How is the package and delivery?

A7: Normally are the wooden boxes, and FCL or LCL container for sea shipping.

|