| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Bead Mill Machine |

|---|---|

| Brand Name: | AllWin |

| Model Number: | SP30 SP50 SP60 SP100 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | USD18000--USD60000/set |

| Payment Terms: | T/T, Western Union, MoneyGram, L/C |

| Supply Ability: | 30sets /month |

| Delivery Time: | 20-30 Working days |

| Packaging Details: | Wooden box |

| Production capacity: | higher production capacity |

| Inner CylinderMatierls: | wearable steel, silicon carbide ceramics |

| Fineness: | less 20um |

| Warranty: | 1 year |

| Power: | 30 37 55 75 kW |

| Volume: | 30-250L |

| Grinding media: | Zirconia bead offered if need |

| Mechanical Seal: | Assembled Double Mechanical Seal |

Low Temperature Grinding Horizontal Bead Mill Machine For White Color Paints Inks

Horizontal bead mill machines are often used in paints, inks, dyes, non metallic mines to decrease the fineness of particles in slurrys, high quality horizontal bead mill machines can enhance the efficiency of production, save the power cost, labor cost, to creat greater values for cooperations.

Grinding process: Single Cycle or series

Application area: Pigments, dyes, paints, inks, food, chocolate, biologics and cell breaks, cosmetics, non-metallic ores and ceramics.

The main feactures:

1. Different materials for meeting dirffent needs :

Adopted high abrasive-resisting materials:silicon carbide ceramics,hard alloy, 9Cr18Mo alloy steel, SUS 304 stainless steel, to guarantee strengthen working life of bead mill machine.

2. Decrease the temperature:

double spiral cooling technology to enhance the space of heat dissipation, with superior material with good thermal conductivity and lower the temperature before coollant come in pipe.

3. Strenghten the fineness:

The different fineness after grindinig can be reached to your different demands, the size of grinding media is matched with the gaps.

4. Enhance the efficiency:

High efficiency with enegry saving, combined grinding and dispersing composnents, nomarlly the efficiency is higher 10-30% than traditional machines.

5. Reduce the labor cost with indicator light

One worker could easily operate 5-10 sets mill machines if mills add the indicator light, decrease the cost of humen. the mill machines will add more if need central control system.

Technical specification:(from 5L to 300L )

| ”Super” SP series of Wet Milling Equipment | ||||

| Type | Working Volume (L) | Power (kW) | Grinding Beads (mm) | Throughput (kg/h) |

| SP5 | 5 | 7.5 | 0.3-3.0 | 20-200 |

| SP15 | 15 | 15 | 0.3-3.0 | 50-500 |

| SP30 | 30 | 30 | 0.3-3.0 | 70-700 |

| SP50 | 50 | 30/37 | 0.3-3.0 | 100-1000 |

| SP100 | 100 | 55 | 0.3-3.0 | 300-3000 |

| SP250 | 250 | 75 | 0.3-3.0 | 450-4500 |

| SP300 | 300 | 90 | 0.3-3.0 | 550-5500 |

Allwin Advantages:

1. Long history and plentiful experiences with 28 year

published over 6 papers about grinding bead mill machines; members of china coat association;memebers of other local province coat associations.

2. Master the core technology of dispersing and grinding

gained 12 letters of patent; China high-tech enterprise; saled more than 10000+ units to customer with great reputation within recently 4 years

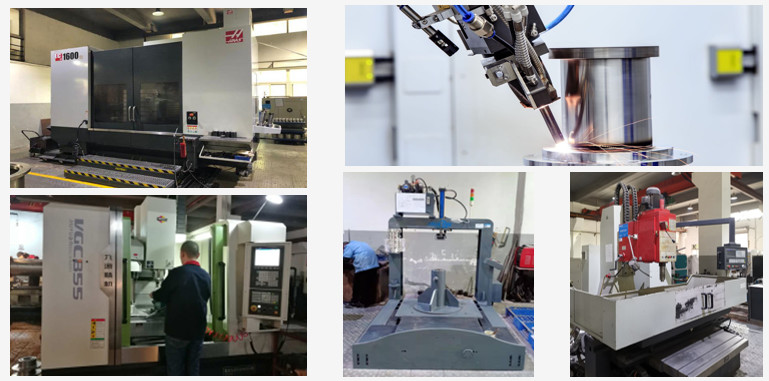

3. With imported and advanced processing machines:

four axises Haas machining center; plasma cutting machine; shaft loading machines; auto-weilding robot;etc

4. high quality customer groups

Akszu Nobel from Netherland, Musashi paint from Japan, Kansai paint from Japan, etc

The main processing equipment

The After sales service:

1. Video instructions for installation and commissioning, if need, we will arrange engineer to your factory.

2. 12-24 hours feedback any customers questions, firstly offer the video help you solving, if need arrange maintenance engineer for you.

The package and shipping:

Packing Details : The machine will be covered with anti-abrasion film and then packed in wooden boxes, then seashipping by FCLor LCL.

The related products( lab bead mills, the Zirconical beads(Different size for meeting different finally fineness)

|