| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Carbon Fiber Fabric |

|---|---|

| Place of Origin: | CHINA |

| Brand Name: | WGSC |

| Certification: | ISO9001 |

| MOQ: | 200㎡ |

| Price: | $14.37-$19.01(㎡) |

| Delivery Time: | 3-7 work days |

| Payment Terms: | T/T |

| Supply Ability: | 500000KGS/month |

| Packaging Details: | Palletize |

| Resin System: | Epoxy |

| Style: | plain/twill |

| Applications: | Aerospace, Automotive, Sports Equipment, Construction, Marine |

| Raw Material: | 3K/12K |

| Features: | Light weight |

| Exportable: | Yes |

| Company Info. |

| Qingdao Wanguo Sanchuan Fiber Technology Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Carbon Fiber Prepreg | Precision Engineered Composite Solutions

Carbon Fiber Prepreg is a high-performance composite material combining carbon fibers with a thermosetting resin matrix (typically epoxy). Prepreg undergoes a controlled partial curing process (B-staging), resulting in a tacky, ready-to-use material that eliminates manual resin application. This ensures consistent fiber-resin ratios, superior mechanical properties, and reduced waste. Key advantages include:

Exceptional Strength-to-Weight Ratio: Delivers 5–7× higher strength than steel at 1/4 the weight.

Uniform Resin Distribution: Automated processes guarantee precise fiber alignment and resin saturation.

Thermal Stability: Operates effectively up to 300°C without significant degradation.

Corrosion Resistance: Impervious to acids, alkalis, and moisture, ideal for harsh environments.

Customizability: Adjustable fiber orientation (0°, ±45°, 90°) and resin systems (epoxy, phenolic) to meet specific performance needs.

Fiber Preparation:

Carbon fibers (e.g., T700, T800) are produced via pyrolysis of polyacrylonitrile (PAN) precursors, achieving high tensile strength and stiffness.

Resin Impregnation:

Fibers pass through a resin bath or film-coating system to achieve uniform resin saturation (30–40% resin content).

B-Staging:

Partial curing at 80–120°C creates a tacky, tack-free state for easy handling and storage.

Layer Consolidation:

Multiple prepreg layers are stacked and aligned using automated cutting and placement systems.

Curing:

Heat and pressure (120–180°C, 0.5–2.0 MPa) in autoclaves ensure full resin curing and void elimination.

Storage:

Store at -18°C to halt curing; thaw for 24 hours at room temperature before use.

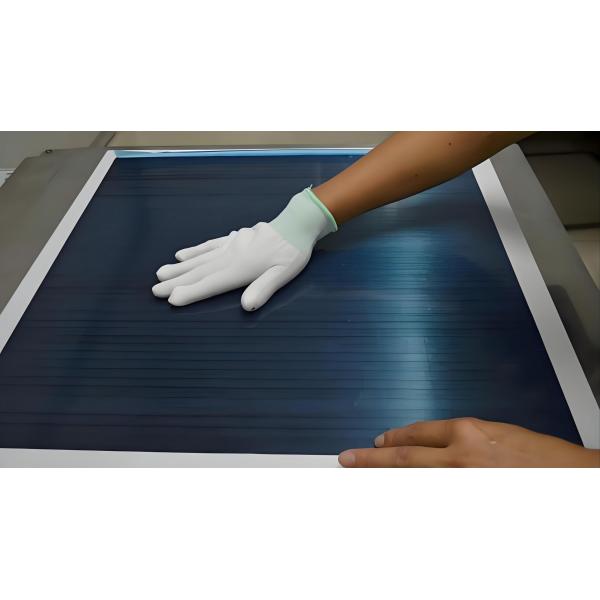

Handling:

Wear PPE (gloves, respirators) to avoid fiber irritation and inhalation hazards.

Curing Parameters:

Maintain strict temperature and pressure controls to prevent warping or void formation.

Surface Preparation:

Clean molds with release agents (e.g., PVA wax) to ensure part release.

| Parameter | Details |

|---|---|

| Material | PAN-based carbon fiber + epoxy resin |

| Fiber Type | T700/T800 (Standard/High Modulus) |

| Resin System | Epoxy, phenolic, or cyanate ester |

| Weight | 160–500 g/m² |

| Thickness | 0.05–0.3 mm |

| Tensile Strength | 3,000–5,000 MPa |

| Elastic Modulus | 70–200 GPa |

| Compressive Strength | 1,500–3,000 MPa |

| Operating Temp | -60°C to +300°C |

| Certifications | ISO 9001, REACH, RoHS |

Aircraft Components: Fuselage panels, wings, and engine mounts. Prepreg’s lightweight rigidity enhances fuel efficiency and payload capacity.

Performance Vehicles: High-strength chassis, suspension arms, and Formula 1 body panels.

Turbine Blades: Reinforces leading edges to withstand high wind loads and fatigue cycles.

Bicycle Frames: Lightweight yet durable frames for racing bikes.

Tennis Rackets: Optimized stiffness-to-weight ratios for power and control.

Robotics & Drones: Structural components requiring high strength-to-weight ratios.

Prosthetics & Implants: Biocompatible, corrosion-resistant materials for load-bearing applications.

Boat Hulls & Offshore Structures: Resists saltwater corrosion and wave-induced stress.

|