| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Ceramic Parts |

|---|---|

| Brand Name: | ZMSH |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | by case |

| Payment Terms: | T/T |

| Supply Ability: | By case |

| Delivery Time: | 2-4 weeks |

| Packaging Details: | custom cartons |

| Material Purity: | Base impurity content < 300 PPM; Surface impurity content < 5 PPM after CVD SiC coating |

| Maximum Operating Temperature: | ≤ 1300℃ |

| Thermal Expansion Coefficient: | Very Low |

| Thermal Conductivity: | High |

| Thermal Shock Resistance: | Excellent |

| Wear Resistance: | Excellent |

| Company Info. |

| SHANGHAI FAMOUS TRADE CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

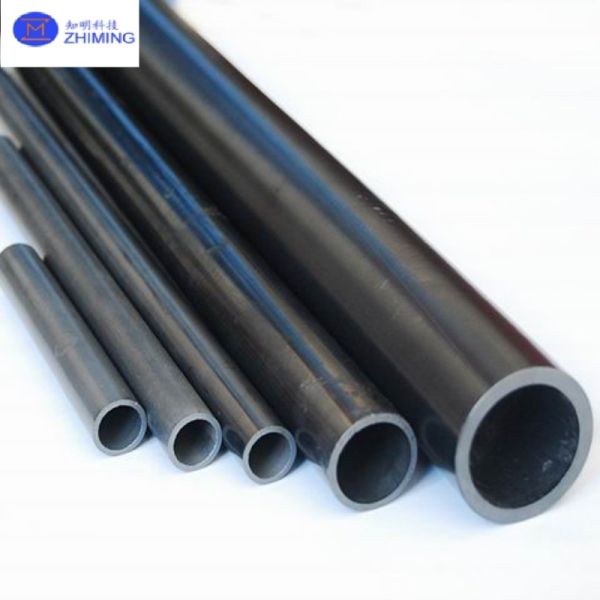

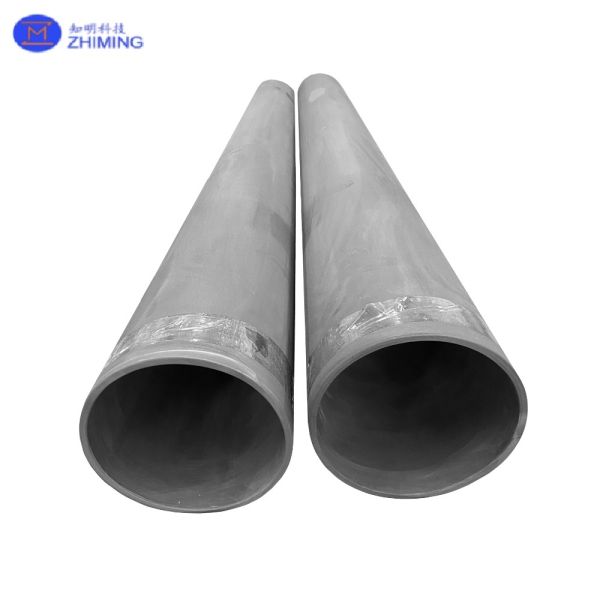

The silicon carbide vertical furnace tube is primarily used as an outer tube, ensuring the uniformity of

atmosphere and temperature inside the furnace. In actual operation, the tube must withstand long-term exposure to high temperatures and complex atmospheric conditions, which demand exceptional purity, thermal performance, and structural stability. Our furnace tubes are produced using advanced 3D printing one-piece molding technology, eliminating potential defects caused by traditional welding or assembly. This ensures a more compact and stable structure. Additionally, with the application of CVD silicon carbide coating technology, material purity and corrosion resistance are further enhanced, allowing the tube to maintain long-term stability even under harsh process conditions. The furnace tube operates at temperatures of approximately 1200℃, meeting the stringent requirements of semiconductor and photovoltaic applications.

One-piece molding with 3D printing

One-piece molding with 3D printing

The integrated structure avoids seams or stress concentration

issues, significantly improving overall strength and reliability.

Ultra-low impurity content

The base material impurity level is less than 300 PPM. After CVD

SiC coating, impurity content in the coated region is reduced to

below 5 PPM, minimizing contamination and ensuring ultra-clean

processing environments.

Excellent thermal performance

With inherently high thermal conductivity, silicon carbide enables

rapid heat transfer and uniform temperature distribution, ensuring

precise temperature control and consistent product quality.

Outstanding thermal shock resistance

Capable of withstanding frequent rapid heating and cooling cycles

at high temperatures without cracking or failure, greatly extending

service life and reducing maintenance costs.

Superior corrosion resistance and durability

The CVD coating enhances purity and provides excellent resistance

to chemical corrosion, allowing the tube to remain stable across

various atmospheres and prolonging overall service cycles.

The silicon carbide vertical furnace tube is widely used in:

Semiconductor manufacturing: For oxidation, diffusion, annealing, and other high-temperature processes requiring strict temperature control and cleanliness.

Photovoltaic industry: In silicon wafer texturing, diffusion, and passivation processes, ensuring stable processing and consistent quality.

New materials and thermal treatment: Suitable for experimental setups and industrial equipment requiring high-temperature uniform heating.

Compared to traditional quartz or alumina tubes, silicon carbide vertical furnace tubes provide significant benefits in temperature resistance, thermal shock stability, and service lifetime. With advanced manufacturing processes and stringent quality control, our product helps customers reduce equipment downtime, improve production stability, and achieve higher efficiency at lower operational costs.

Item | Specification | Description |

|---|---|---|

Material Purity | Base impurity content < 300 PPM; Surface impurity content < 5 PPM after CVD SiC coating | Ultra-high purity, ensuring minimal contamination |

Maximum Operating Temperature | ≤ 1300℃ | Stable long-term performance in high-temperature environments |

Thermal Expansion Coefficient | Very Low | Excellent dimensional stability during thermal cycling |

Thermal Conductivity | High | Efficient heat transfer and uniform temperature distribution |

Thermal Shock Resistance | Excellent | Withstands rapid heating and cooling without cracking |

Wear Resistance | Excellent | High hardness and durability for extended service life |

Corrosion Resistance | Excellent | Stable under various process atmospheres |

Manufacturing Process | 3D printing one-piece molding + CVD SiC coating | Advanced technology ensuring structural integrity and purity |

Q1: What are the main applications of silicon carbide vertical

furnace tubes?

A1: They are mainly used in the semiconductor, photovoltaic, and

advanced materials industries for high-temperature processes such

as diffusion, oxidation, annealing, and passivation. The tubes

ensure uniform atmosphere and temperature inside the furnace,

improving product yield and consistency.

Q2: What is the maximum operating temperature?

A2: The furnace tube operates at approximately 1200℃, while

maintaining excellent structural stability and reliable

performance.

Q3: How does it compare with traditional quartz or alumina furnace

tubes?

A3: Compared to quartz or alumina tubes, silicon carbide tubes

offer superior temperature resistance, thermal conductivity,

thermal shock resistance, and longer service life. In addition,

they have much higher purity and lower impurity levels, making them

more suitable for advanced semiconductor and photovoltaic

processes.

|