| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | AMR Autonomous Mobile Robot |

|---|---|

| Brand Name: | Huayide |

| Model Number: | VFR-CL2,VNA Fork-type AMR |

| Certification: | CE&ISO |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | can be negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 900000KGS PER Month |

| Delivery Time: | 10-20 working days |

| Packaging Details: | Plastic banding+Stretch film wrapped,easy loading and unloading with standard forklift truck or pallet jack . |

| Product Name: | Very Narrow Aisle Fork-type Autonomous Mobile Robot |

| Use: | Warehouse Pallet Stacking And Handling |

| Type: | VNA Fork-type AMR |

| Dimensions L * W * H: | 1500*1500*1950 mm |

| Minimum rotation radius: | 800 mm |

| Lane width: | 1650-1800 mm |

| Self weight: | 1300 Kg |

| Rated load capacity: | 1000 Kg |

| Load walking speed: | 1.0 m/s |

| Adapt pallet: | 1200 * 800 * 150, 1200 * 1000 * 150, 1100 * 1100 * 150,1200*1200*150 |

| Company Info. |

| Anhui Huayide Intelligent Storage Equipment Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

VFR-CL2 ( VNA Fork-type AMR )

Very Narrow Aisle Fork-type Autonomous Mobile Robot

VFR Fork-type AMR CL Serie stype 2

• VFR-CL2 is Very Narrow Aisle Fork-Type AMR CL Serie stype 2,

which is based on VFR-CL1 and enhances flexibility and compactness;

• The VFR-CL2 adopts a "circular chassis design" that can rotate

and change direction in place in extremely narrow tunnels or in

front of conveyor lines, enabling "one in one out mode" and

"extremely compact space connection";

• VFR-CL2 also adopts the "two-level telescopic gantry technology",

with a minimum height of less than 2m for the whole machine, which

can enter and exit common elevators and achieve flexible handling

across floors;

• In addition, VFR-CL2 can also be connected to European standard

pallets;

VFR-CL2 supports optional functions such as 3D space obstacle

avoidance and 3D container recognition

VNA Fork-Type AMR· AMR Autonomous Mobile Robot · Made In China

Performance Characteristics

—

Specifications | CL2 | Positioning accuracy (mm) | ±5 |

Dimensions L * W * H (mm) | 1500*1500*1950 | Cross height capability (mm) | 5 |

Minimum rotation radius (mm) | 800 | Span capacity (mm) | 30 |

Lane width (mm) | 1650-1800 | Climbing ability (%) | 3 |

Self weight (Kg) | 1300 | Rated operating time (h) | 12 |

Working temperature (° C) | 0-40 | Charging time (h) | 2 |

Working humidity (%) | 10-90 | Charging cycle times (0-80%) | ≥1500 |

Rated load capacity (Kg) | 1000 | Charging method | Automatic and manual |

Maximum pick and place height (mm) | 2200 | autonomous obstacle avoidance | √ |

Navigation method | QR code/SLAM+QR code navigation | passive safety | √ |

Maximum walking speed (m/s) | 1.2 | Warning device | √ |

Load walking speed (m/s) | 1.0 | Emergency stop switch | √ |

Adapt pallet | Type: Chuanzi pallet (specific working conditions can also support

Tianzi pallet) | ||

VNA Fork-Type AMR· AMR Autonomous Mobile Robot · Made In China

VFR-CL2 Advantages

—

● Turn around in the tunnel, support one in one out mode, faster

speed

● Support optional 3D container recognition, intelligent

recognition of complex containers (European standard pallets, long

pallets, racks, rolls)

● Support flexible cross layer handling

● Compatible with European standard pallets

● Support optional 3D space obstacle avoidance to ensure safety

● Narrow alleyway ● Pick up immediately upon arrival ● Accuracy ±

5mm

● Complies with the international standard IS03691-4. Overload

alarm, cargo height alarm, extended obstruction alarm, gantry tilt

alarm, high-altitude obstacle avoidance alarm

● Intelligent recognition tray, adaptive drive wheel pressure

adjustment

3D container recognition:coil material docking

VNA Fork-Type AMR· AMR Autonomous Mobile Robot · Made In China

Product Application

—

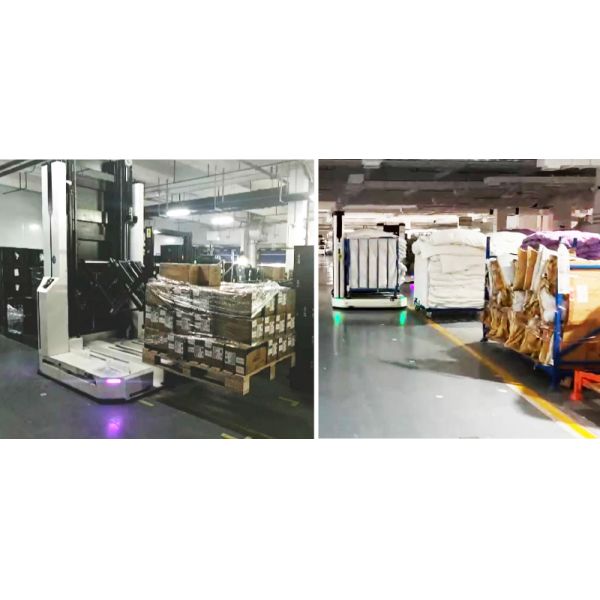

One in one out mode / Cross layer transportation

European standard pallet docking

3D container recognition: "rack/cage" docking

3D container recognition: "rack/cage" docking

VNA Fork-Type AMR· AMR Autonomous Mobile Robot · Made In China

VFR Advantages

—

VNA Fork-type AMR Advantages

Very Narrow Aisle Fork-type Autonomous Mobile Robot

Rich application scenarios: not only can it seamlessly connect with the ground pallet, but it

can also be flexibly lifted to accurately dock with various

connection ports, and can be extended to high positions to achieve

efficient docking with heavy duty pallet rack; Seamless

coordination with elevators ensures safe, timely, and fully

automated operation within warehouse facilities.

Intelligence: The laser radar intelligently determines the angle of

the pallet fork hole and autonomously corrects it to complete the

pallet fork removal.

Security and stability: Considering the complexity of scene security from all aspects,

multiple types of sensors have been added, which comply with CE

certification and ISO3691-4 international standards.

High precision and efficiency: Our self-developed multi-sensor fusion algorithm utilizes SLAM

technology for global positioning, combined with QR codes and

reflective stickers for precise positioning, with a positioning

time of only 1.5 seconds.

Adaptability: Suitable for multi material pallets, with a brand new and robust

chassis structure, ensuring stability under heavy loads and ground

adaptability.

High density storage: extremely narrow tunnels, as low as 1.65 meters, compact body,

storage density increased by 80% compared to traditional stacks;

Optimize storage efficiency in the floor warehouse environment and

support automated high-density access in vertical layout

facilities.

VNA Fork-Type AMR· AMR Autonomous Mobile Robot · Made In China

Project Introduction

—

Pharmaceutical industry project: With a storage capacity of 125000 pieces, 100% compliant with GSP third-party logistics standards, it can support a sales scale of 6 billion yuan for 3-5 years.

Electronic manufacturing industry project: The project design plans 9600 pallet storage locations and introduces core equipment such as side fork mobile robots to achieve precise and fast operation processing. At the same time, the supporting intelligent logistics system also has high flexibility and scalability, providing a solid logistics foundation for future business growth. VFR connects the logistics and handling operations within the factory, achieving 100% automation of handling.

Stationery Industry Project: Achieving Intelligent and Automated Logistics Operations in Pen Manufacturing Plants. VFR significantly enhances the efficiency of internal material storage and handling within factories, meeting enterprises' demands for efficient storage and rapid outbound of raw materials, semi-finished products, finished goods, and other materials. This greatly improves factory production efficiency and logistics management capabilities.

Home textile industry project: Implement intelligent scheduling of logistics vehicles in the park, connect logistics systems in four storage areas and one workshop, and achieve automated logistics operations within the factory.

Food Packaging Project: Covering differentiated requirements such as standard load capacity, 1.3-ton heavy load, and 4.2-meter-high lifting. Customized equipment solutions for the entire process of coil storage and transportation. Ensure the safe and efficient transportation of coil materials. Effectively supporting the sustainability and competitiveness of customer supply chains.

VNA Fork-Type AMR· AMR Autonomous Mobile Robot · Made In China

ABOUT US

—

Anhui Huayide Intelligent Storage Equipment Co., Ltd. (the promitive name Anhui Huarunde logictics equipment Co., Ltd, Establised in 2009) is located in Hefei Binhu Science City, Anhui Province. It focuses on the development and promotion of intelligent logistics equipment, integrating scientific research and development, manufacturing, system integration, marketing and engineering services, committed to providing world-class internationally competitive intelligent logistics equipment, products and solutions, covered automation and intelligent manufacturing. Our products are widely used in power, automotive, chemical, logistics, public utilities, manufacturing and other industries.

We have strong technical, relying on the deep cooperation between Anhui Polytechnic University, research institute of University of Science and Technology of China and well-known enterprises. In the process of product research and development, it has absorbed a large number of advanced technologies and concepts,possesses comprehensive technical research and development capabilities of intelligent logistics equipment. We have extremely profound accomplishments project planning, intelligent manufacturing, intelligent electrical control, computer software development, and engineering project management .

We have:

professional shelf raw material strength testing machine , column

load testing machines and beam load testing machines.

We have:

a complete set of shelf surface coating quality testing equipment:

cross-cut testing machine, cupping testing machine, electronic

magnetic thickness gauge, gloss measuring instrument, salt spray

testing machine, etc.

We have passed :

IS09001 quality system certification, IS014001 environmental system

certification, ISO18001 occupational health system certification.

Tested by the European research institute, we passed various

indicators such as safety and environmental protection, obtained CE

certification, and obtained a sales pass to enter the European

market.

Company Details ( Click to enter )

Production Line ( Click to enter )

VNA Fork-Type AMR· AMR Autonomous Mobile Robot · Made In China

|